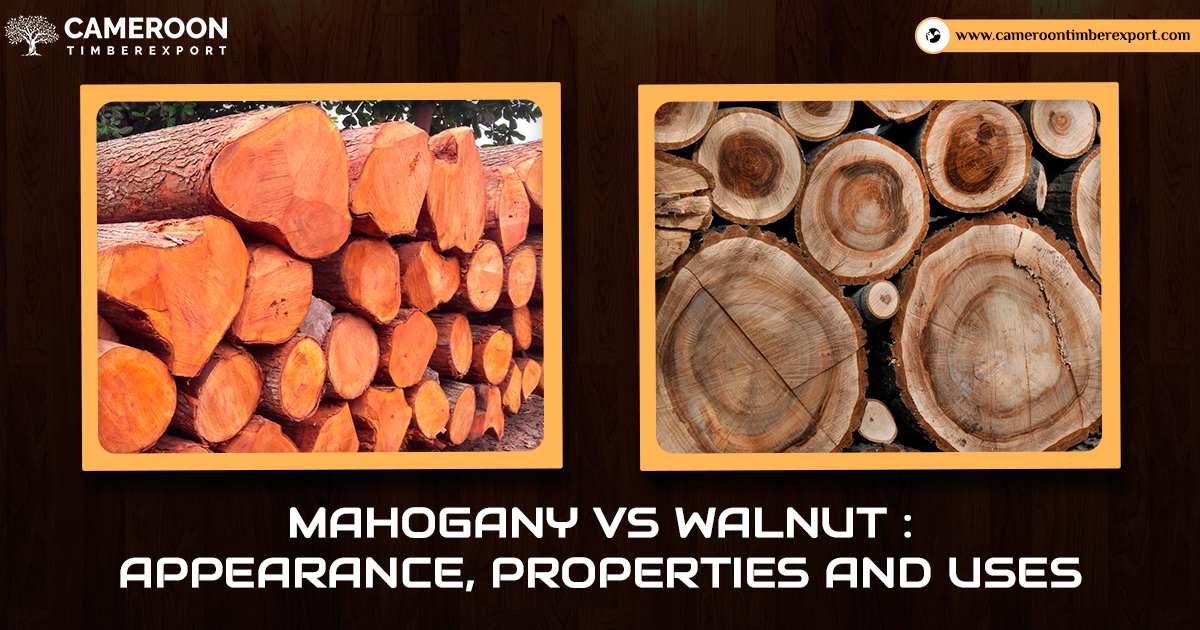

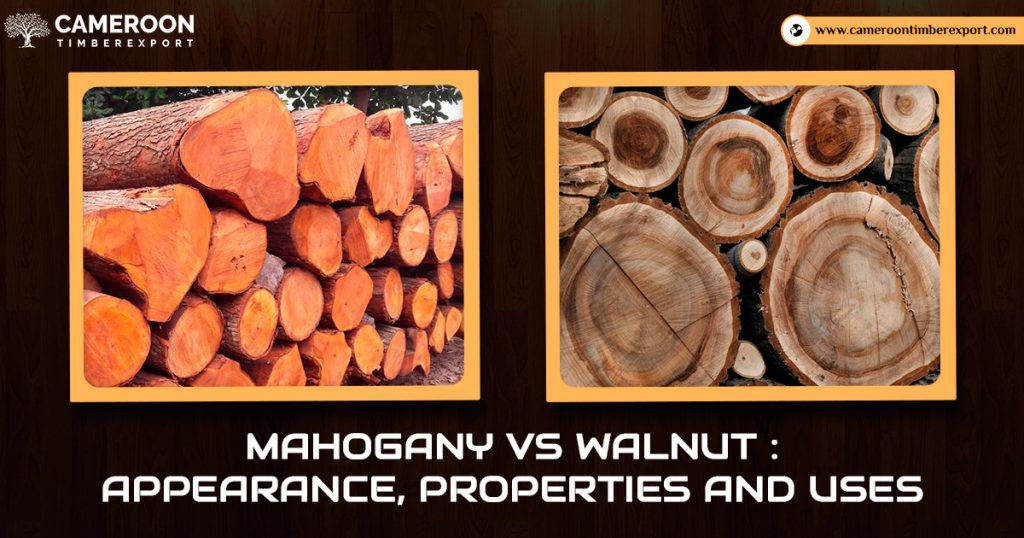

Both walnut and mahogany are among the top choices for high-end woodwork and furniture making due to their incredible appearance and outstanding physical properties like hardness and durability.

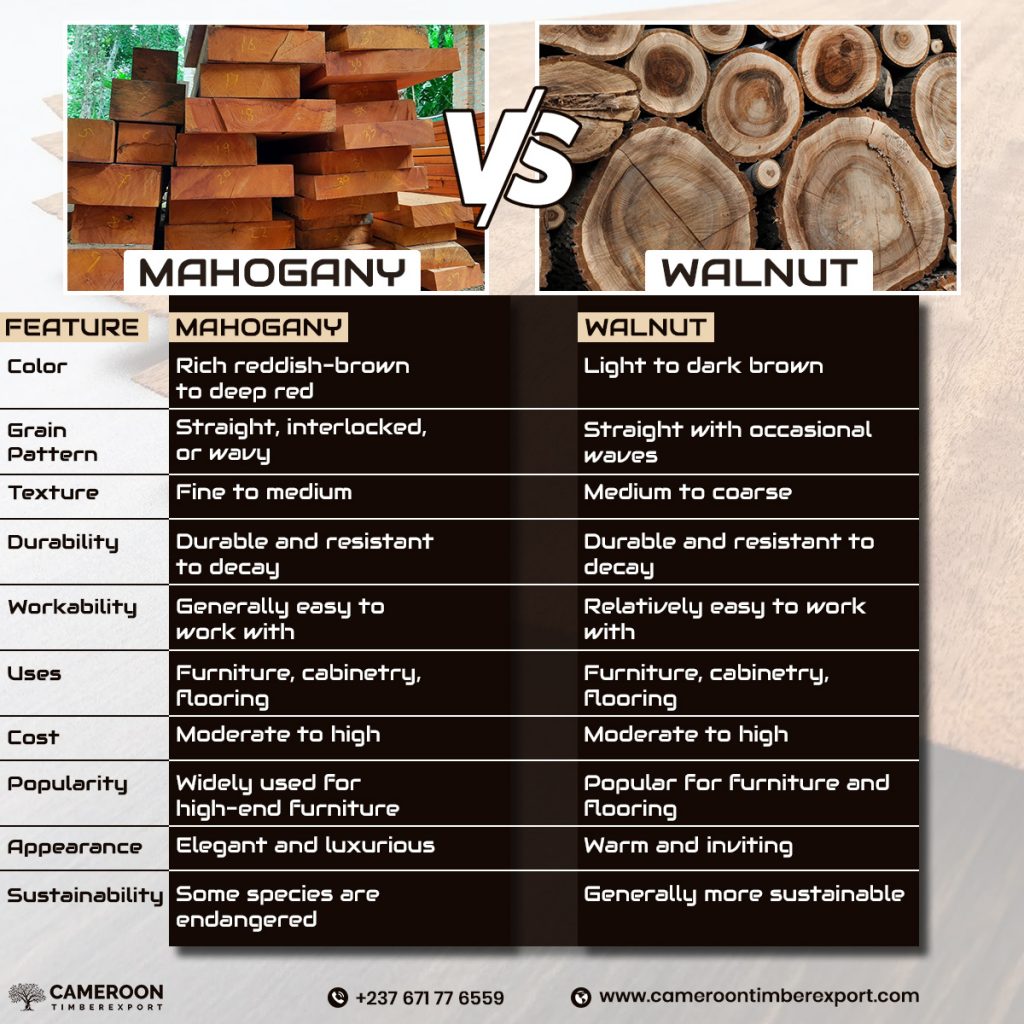

While walnut wood and mahogany have many similar uses, there are also many differences between these two timber types based on color, texture, grain patterns, and structure. Walnut is darker with a dusty appearance and straight grain, while mahogany is slightly brighter with a reddish-brown color and more irregular grain. Mahogany wood is generally harder than walnut, which is stronger and more shock-resistant. Also, walnut wood is more expensive than mahogany due to its high demand and limited availability.

We will learn about more such differences between mahogany wood and walnut in this article.

Introduction to Mahogany Wood

Mahogany is a strong and reliable hardwood originating from Central and South America, Africa, and Asia. It’s particularly famous for its captivating reddish-brown hue. Mahogany lumber finds widespread application in the manufacturing of luxurious furniture, cabinetry, outdoor projects, and musical instruments.

Distinguished by its stunning aesthetics, high durability, and exceptional resistance to decay, mahogany is a popular choice for the construction of high-quality furniture, including beds, chairs, tables, and cabinetry. Its versatility also makes it suitable for use in shipbuilding and other applications like building windows and doors. Due to its exceptional acoustic properties, mahogany is often used in the manufacturing of musical instruments like guitars, drums, and pianos.

About Walnut Wood

Walnut wood, a hardwood commonly found in the United States, including eastern and central America, is obtained from the walnut tree, which is a beautiful and giant tree that can attain heights of up to 100 feet (30.5 meters) and a trunk diameter of 4 feet (1.2 meters). Known for its unique and attractive grain patterns and dark color, walnut wood is favored for its sturdiness and high durability. These qualities make walnut timber an obvious choice for a variety of woodworking projects, ranging from furniture making and cabinets to flooring, doors, windows, wall panels, and musical instruments.

Walnut wood is often favoured by woodworkers as the best tonewood for crafting musical instruments such as guitars, pianos, and drums, mainly because of its exceptional acoustic properties and also for its beautiful appearance. It is also commonly used for carving and turning.

Pros & Cons of Mahogany Lumber

Mahogany is a popular hardwood known for its exceptional durability, stunning appearance, and resistance to scratches, dents, and wear. It demonstrates a high dimensional stability and is resistant to warping over time. It’s also easy to work with and shape with tools like saws, chisels, and sandpaper. Featuring a rich reddish-brown color and notable grain, Mahogany gets darker and more beautiful over time. Its unique grain patterns and dark streaks with appealing designs make it even more attractive.

Due to high demand and low availability, Mahogany is often an expensive wood, often surrounded by availability and sustainability concerns. It’s a heavy wood and not very suitable for lightweight projects.

Pros & Cons of Walnut Lumber

Walnut lumber remains one of the top choices for woodworkers around the world. Celebrated for its captivating appearance and natural resistance to decay and deterioration. The wood is easy to work with, manage and reliable, with a low risk of deformations.

There are some drawbacks as well to using walnut wood. It’s one of the most expensive hardwoods out there, with a very high demand. Handling and transportation can be challenging due to its weight. Natural toxins present in the walnut wood might render it unsuitable for kitchen items like cutting boards.

Mahogany vs Walnut Wood : What’s the Difference?

Both mahogany and walnut are strong, attractive and durable hardwood choices with their respective properties which make them suitable for a variety of applications. If you’re confused between mahogany and walnut timber for your next project, here’s everything you need to know about the difference between the two.

Appearance

Mahogany and walnut may appear practically similar, especially after finishing, but there is a very clear, notable difference in color. Walnut features a dark brown, dusty hue, often highlighted by a hint of red or purple. Its multi-tonal appearance makes it ideal for furniture and decorative uses. In contrast, mahogany has a distinct, bright reddish-brown color, graced with an uneven but attractive grain pattern, which makes it a perfect choice for beautiful, high-end furniture and musical instruments.

The choice between mahogany and walnut wood based on appearance only can be difficult, as both offer rich, appealing colors, delivering great aesthetics. Walnut maintains a consistent brownish look over time, while mahogany’s reddish-brown hue can darken over time to give it a glossy sheen.

Strength & Durability

Mahogany is superior to walnut wood in terms of density and strength. In other words, mahogany wood is heavier and stronger than walnut, which makes it higher resistant to scratches, dents, and wear. Mahogany also has great moisture resistance and can withstand pests and decay, making it a superb choice for outdoor furniture and marine applications like ship construction. In contrast, walnut is less resistant to moisture and may warp or split in humid conditions.

However, walnut wood depicts higher flexibility in varying humidity conditions than mahogany. It’s also more stable. Both walnut and mahogany are tough and durable woods that can endure for generations with proper care.

Stability & Hardness

Walnut boasts a Janka hardness rating of around 1010 lbf, which indicates medium density with good hardness. It’s extremely stable against warping or deforming due to climate change. In other words, it won’t shrink or expand considerably over time and has impressive strength, making it a great choice for furniture. Mahogany has an 830 Janka rating, which makes it less hard than mahogany, but it offers great dimensional stability and low shrinkage. The durable wood is perfect for furniture construction.

Walnut’s higher Janka rating and robustness are the reasons why woodworkers love this wood. Mahogany is, though, equally popular and a wonderful choice for a range of projects.

Workability

Walnut wood features an open grain structure, making it easy to shape and carve. It’s prized for its outstanding workability both with tools and hands, making it ideal for complex detailing. As a wood with great stability and strength, it can deliver consistently good results in various woodworking projects.

Mahogany’s tighter grain structure and higher density can sometimes present challenges in certain woodworking tasks like intricate carving and detailing, but it’s overall easy to work with. Mahogany is particularly famous for its high durability and suitability for various machining operations, making it an incredible choice for crafting furniture and instruments.

With the right tools and expertise, both mahogany and walnut wood can produce outstanding results. Walnut is particularly suitable for detail work, while mahogany is the best for projects requiring resilience.

Availability & Price

Walnut is a highly popular wood favoured by woodworkers for its gorgeous aesthetics, exceptional strength, and versatile applications. Though the cost of walnut wood varies with grade and location, almost all species are quite expensive and generally costlier than most other hardwoods.

Mahogany is a comparatively economical choice for those looking for premium timber. The beautiful, strong and durable wood is particularly favored for furniture, cabinetry, and musical instruments. Mahogany’s cost also depends on its origin and species, but it’s usually lower than walnut wood’s price.

Maintenance

As a durable wood with natural resistance to decay and insects, walnut wood can last very long with minimal upkeep. To maintain its beautiful color and appearance and prevent discoloration over time, routine cleaning and applying polishing or finishes like oil or wax is more than sufficient.

Mahogany, on the other hand, might ask for more care. Applying protective finishes like varnish or oil once during construction can provide long-term protection against moisture and wear. Even though the wood is resistant to decay and insects, it must be routinely maintained to avoid issues.

Uses

Both walnut and mahogany woods find versatile applications owing to their unique and wonderful characteristics. Walnut’s open grain structure and moldability make it a preferred choice for detailed carvings and moulding as well as for building fine furniture and decorative pieces. The objects made from walnut wood both look great and are strong and durable.

Mahogany wood features a tighter, more prominent grain and impressive durability, which make it ideal for a wide range of applications, from high-quality indoor furniture and musical instruments to outdoor projects and flooring. Its natural reddish-brown color is favored by many over walnut’s dark hue. Mahogany’s resistance to moisture and insects makes it perfect for outdoor applications as well as shipbuilding and premium cabinetry.

Mahogany vs Walnut : Which is Better?

The choice between mahogany and walnut timber is not easy. Both are very attractive and strong wood species. When comparing the two, you must look at their distinctive characteristics and qualities, which make them suitable for different uses.

The right wood type for your particular project will also depend on your specific needs, tastes and goals. Contact us to consult with a specialist woodworker to make the right choice. If you’re ready to buy timber, do visit Cameroon Timber Export Sarl to explore our wide range of hardwood and softwood timber. Buy mahogany and walnut hardwoods at the best price online with doorstep delivery anywhere in the world.