Meranti is a durable hardwood with soft to medium density and light or dark golden reddish color, which depends on the origin of the wood. It is primarily used in internal applications and projects such as home/office interior, flooring, furniture, window, moulding, etc. In terms of workability, Meranti cuts, nails, glues, screws and sands easily. The wood is easily available and moderately priced. Here’s everything you need to know about Meranti timber, its properties, uses and availability.

CameroonTimberExportSarl is a leading exporter & seller of Meranti hardwood timber, logs and slabs. We supply to all locations around the world, including Europe, Africa, Australia, Western Asia, and America. For the best quality Meranti wood at cheap prices, contact us today.

Meranti Timber Introduction

Meranti has many types based on the species it is produced from. Some of these include Shorea pauciflora, S. acuminata, S. platycarpa, and S. platyclados. The wood is commonly known as dark red meranti or light red meranti based on its color. It is also sometimes called Philippine Mahogany because of its mahogany-like features and appearance.

Meranti is produced all over the world, but it is native to Indonesia and primarily grows in Kalimantan, Malaysia, Singapore, Thailand, and the Philippines. In other countries where the wood is not locally produced, it is imported from other regions.

The Meranti trees are generally 65-130 ft tall and have a 3-6 ft trunk diameter. They are averagely strong and have moderate durability. Let us now look at some of the most important meranti wood properties in detail.

Technical specifications

Crushing Strength: 7,070 lbf/in2 (48.8 MPa)

Modulus of Rupture: 12,710 lbf/in2 (87.7 MPa)

Average Dried Weight: 42 lbs/ft3 (675 kg/m3)

Janka Hardness: 800 lbf (3,570 N)

Elastic Modulus: 1,743,000 lbf/in2 (12.02 GPa)

Specific Gravity (Basic, 12% MC): .55, .68

Shrinkage: Radial: 3.9%, Tangential: 7.8%, Volumetric: 12.5%, T/R Ratio: 2.0

Meranti Wood Properties, Pros & Cons

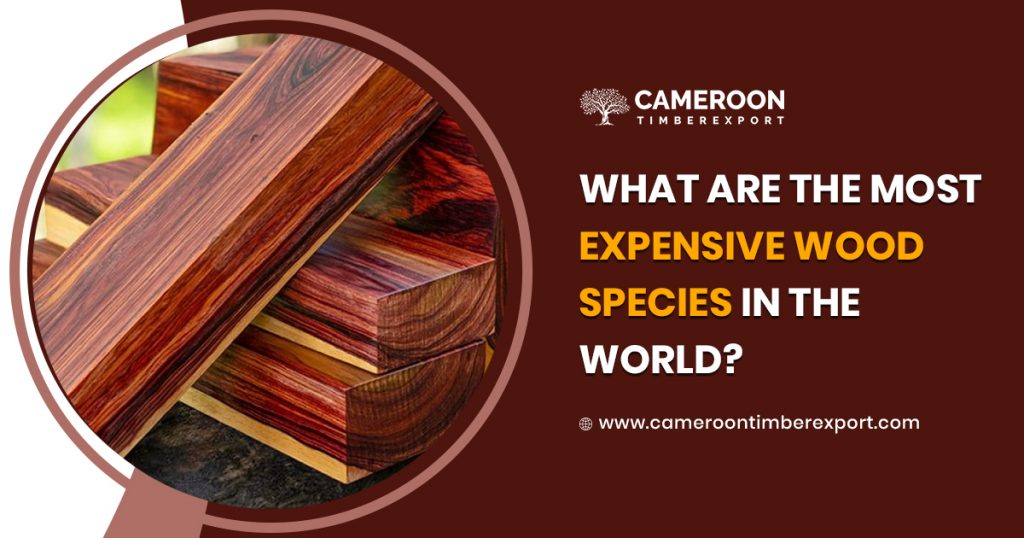

Color: Depending on the type, Meranti can be light red or dark red (heartwood) and has a lighter sapwood, but the dark reddish wood with white resin streaks is the most common.

Grain: Meranti wood grain is normally straight but can also be interlocked and has a coarse texture with a low natural lustre.

Endgrain: It is rather easy to identify Meranti wood because of its porous end-grain, having large or very large pores in no fixed arrangement.

Resistance & Durability: Meranti is generally soft or medium hard and rated as moderately durable. It has decent resistance to decay but is prone to insect attack, bugs and marine borders. The wood has average hardness and is relatively stable.

Workability: The best thing about Meranti is that it is easy to work with both hands and machines. The wood glues, stains, paints and finishes well. It is also easy to nail and has good sticking properties. However, the presence of interlocked grain can sometimes lead to troubles during planing. Some species having a little silica content can cause a blunting effect on woodworking tools. Also, Meranti is known to be poorly responsive to steam-bending.

Drying: Meranti is reported to dry easily and rapidly. In just about 2 to 3 months, the moisture content in wood can reduce from 60 per cent to 18 per cent when kept in the open air under covers. It undergoes little degradation when naturally drying.

Meranti Wood Types

Meranti can have different species based on origin and properties. The most common ones include Dark Red Meranti, White Meranti, Yellow Meranti and Light Red Meranti.

As the name suggests, the main difference is in color. Light Red Meranti has a pale straw color, while dark red Meranti is dark reddish or brown. While Meranti has a yellowish-orange heartwood, and Yellow Meranti is yellowish-brown. Other properties are nearly the same.

Meranti Wood Uses

Meranti has poor or moderate durability and rot resistance, which is why it is generally preferred for interior work. Due to the above listed meranti wood properties it is Commonly used as plywood, flooring, interior furniture, veneering, construction, windows, doors, joinery, and boatbuilding.

Meranti Wood Price & Availability

Meranti is widely harvested and grows in many locations around the world. It is therefore easily available. Even the imported wood has a moderate price because of its easy and ample availability. However, some species of this wood are added to the IUCN Red List of Threatened Species and may not be as easily available. Contact your local wood supplier or Cameroon Timber Export Sarl for details.

Your search for a reliable Meranti wood supplier/exporter ends here. We can provide top-quality wood products at the best price in the market with outstanding after-sales support. Contact us today to know more.