Oak is one of the most prized and sought-after hardwoods among woodworkers around the world. The Quercus genus, from which oak wood comes, is known to have about 500 species of trees and shrubs scattered across all over the planet. All species of oak can be broadly divided into two categories: red and white oak.

Many species of oak are found in Britain and other countries across Europe. Most of these belong to the white oak category.

The difference between red oak vs white oak is more complex than just their colours. While most white oaks have a light colour, there are exceptions as well. The same is true for red oak. If you’re looking to know about the various differences between white and red oak species, this article is for you. Let’s start with a brief introduction of the two types of oak.

What is oak wood known for?

Oak is a hardwood, and as such, it’s known for its amazing strength and durability, which might differ from one oak species to another. Many species of oak are naturally resistant to decay and a variety of insects. The colour of oak ranges between light brown and dark reddish across species.

Oak is used in everything, from making fine furniture to building construction, flooring, and outdoor projects such as boatbuilding. Many species of oak are inexpensive and easily accessible, particularly in their native regions. The two most common oak types are white oak and red oak.

There are some important differences between white oak and red oak. If you are planning to choose between these two wood types for your next project, reading this article will help you with the decision.

About White Oak

White Oak trees, scientifically known as Quercus alba, are renowned for their remarkable size. When allowed to grow naturally, these oak trees can reach exceptional heights, with an average height of around 80 feet and a breadth nearly matching their height when considering their extra-large branches.

Despite their imposing stature, White Oak trees are slow-growing trees. Native to North America, These trees produce a significant number of acorns (a type of fruit), which serve as a vital source of food for various wildlife and avian species.

White oak is a strong, beautiful and durable hardwood which is used in many applications ranging from construction to interior trim, furniture making, flooring, and outdoor projects.

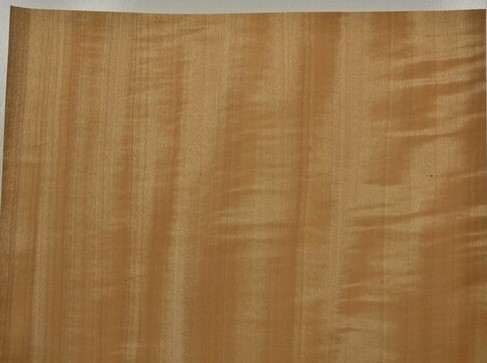

In terms of appearance, White Oak features a lighter (brownish) colour compared to its red oak counterparts, which are on a darker side. Its bark has a rough and ashy texture with deep ridges, which sometimes makes it favoured by some landscaping enthusiasts.

In contrast to the rugged bark, White Oak leaves exhibit a smoother, more rounded appearance without sharp angles.

About Red Oak

The Red Oak – scientific name Quercus rubra or Quercus borealis – is not as tall as the White Oak but can still reach up to 75 feet in height. They are also less wide in terms of the length of branches.

Branches of a red oak tree have a more compact spread, making the tree look leaner and slimmer than white oak trees. Red Oak trees, contrary to their whiter counterparts, grow more quickly, often achieving up to 20 feet in height in just a decade. They can grow in various soil types and environments and provide sustenance and shelter for numerous wildlife species.

Red Oak timber can be identified by its significantly darker hue, especially when compared to White Oak. Their bark is smoother with fewer prominent ridges. In contrast to the rounded edges of White Oak leaves, Red Oak leaves have sharper tips.

Colour & Appearance

Red Oak boasts pinkish or salmon undertones, radiating warmth, while White Oak leans toward slightly darker brownish or beige hues for a more subdued look.

Red Oak exhibits a more aggressive grain pattern compared to the smoother appearance of White Oak. The pronounced grain of Red Oak not only improves its character but also provides durability, making the wood resistant to dents and scratches. It’s a great choice for busy commercial settings and households with kids and pets. While Red Oak showcases longer rays, White Oak has mineral rays, which make it a better option for contemporary designs.

When it comes to flooring, the comparison between Red Oak and White Oak unveils a striking contrast in colour and grain patterns. One notable aspect to consider when choosing between the two is staining. Both Red and White Oak readily accept stains, but White Oak is better when it comes to contemporary trends favouring greyish or white stain colours. Its natural brownish hue complements these shades beautifully, giving your project a modern and timeless aesthetic. On the other hand, the difference between White Oak and Red Oak becomes less pronounced as you use medium and darker stain shades, and they might even converge in appearance.

Hardness & Strength

When contemplating the choice of Oak timber for your upcoming woodworking project, it’s vital to compare the hardness. The Janka hardness rating of red oak is 1290 lbf. In contrast, White Oak enjoys a slightly higher hardness rating at 1360 lbf, making it stronger and more resistant to impacts.

However, it’s crucial to note that once both Red Oak and White Oak hardwoods are properly finished and sealed, their performance becomes nearly identical. Both become durable, long-lasting materials after finishing that can beautifully grace your projects, no matter the application. Since both red oak and white oak are nearly equally strong, your selection should ultimately depend on your aesthetic and functional preferences.

Durability

In terms of durability, there is a minor difference between the two hardwoods. Red Oak, with a Janka hardness rating of 1290 lbf, exhibits great strength and stability, making it well-suited for various applications. On the other hand, White Oak boasts an even higher rating at 1360 lbf, making it strong and more resistant to wear and impact.

Special attention must be paid when choosing oak furniture or flooring for high-traffic areas or places prone to heavy use. White Oak does fairly well in projects where exceptional durability is required, making it a preferred choice for flooring and furniture. However, both woods, once properly finished and sealed, offer great durability and longevity, ensuring that your furniture or flooring lasts for decades.

White Oak provides better resistance to moisture due to its closed-grain nature. This is why it is commonly used for making wine and beer barrels and boats.

Workability

Comparing the workability of Red and White Oak will give you a good idea about the right wood for your next project. Red Oak is generally easy to work with various tools, but it sometimes splinters and might require special attention during cutting and finishing. In contrast, White Oak can be slightly difficult to work with owing to its extra hardness, but it has superior bending qualities, making it a perfect choice for steam bending for intricate joinery applications.

Availability & Price

Both red and white oak are fairly inexpensive and are easily accessible around the world. However, depending on your location, one type of oak might be more easily available than another. In comparison, white oak might be a little more expensive.

Red Oak is more common and budget-friendly, making it a popular choice for many woodworking projects. In contrast, White Oak is typically less available and slightly more expensive owing to its superior durability and unique grain pattern.

Maintenance

When it comes to maintenance, both white and red oak require nearly similar care. This includes regular cleaning and dusting. Avoid excessive access to moisture and/or sunlight. Make sure to apply protective finishes and polish regularly which helps protect their beauty and longevity.

Because Red Oak has a more porous grain, it may absorb dust and moisture quickly and might need extra attention to prevent dirt buildup. In contrast, White Oak’s closed grain makes it easy to clean and maintain.

Uses

Both white and red oak find diverse applications due to their outstanding physical qualities, incredible appearance, and easy availability and affordability.

Red Oak is a versatile lumber that is used for furniture, cabinets, flooring, doors, windows, plywood, and interior trim. Its reddish hue adds character to these projects. White Oak, which is an equally beautiful and more durable wood with great resistance to moisture, is often preferred for marine and outdoor applications including boat building and barrels for wine. It’s also a good choice for fine exterior furniture. The high durability and stability of white oak make it suitable for flooring in high-traffic areas.

Red oak vs White Oak : Which is Better?

To conclude, both white and red oak are excellent hardwoods. Both are strong and beautiful. However, white oak is more durable and has better resistance to rot and moisture. Red oak is not very suitable for outdoor projects like boatbuilding. White oak is usually slightly darker than red oak.

If you need help selecting the right timber for your project, contact Cameroon Timber Export SARL to explore our wide range of premium quality, sustainable timber available in various sizes with worldwide shipping.