When looking to buy wood for your project, you have two options – buy solid wood timber or go with manufactured wood. Of course, buying and using solid wood is generally a costlier option. Moreover, in some cases, manufactured wood turn out to be better or more durable than real wood. If you are looking to learn about the different types of manufactured boards, here you go.

What is Manufactured Wood?

As the name suggests, manufactured wood is a type of wood that is manufactured and is not naturally produced solid wood. Manufacture boards are made by combining different wood pieces along with glue and other things to produce a stable and possibly more durable piece of wood. The best thing about manufactured wood is that it costs less than natural solid wood but can be as strong and durable. It is ideal for a variety of woodworking projects ranging from construction to furniture making, flooring and others.

In order to select the right manufactured boards, you must about the different types of manufactured wood boards along with their qualities and drawbacks,

Types of Manufactured Boards

The Most Common Types of Manufactures Boards Include:

- Plywood

- Particleboard/ Chipboard

- Fiberboard

- MDF (Medium Density Fiberboard)

- Veneer

Plywood

Plywood is manufactured by combining alternate layers of wood such that their grain is at right angles to each other. The result is a very strong and durable wood with high resistance to tearing. The layers in plywood are combined under high pressure and controlled heat conditions to achieve a robust product. Waterproof glue is used to manufacture plywood that is water-resistant and can be used outside. Depending on the material used, plywood is available in different types, including veneered plywood and marine plywood.

Particleboard / Chipboard

Particleboard, as the name suggests, is made from wood particles or smaller wood pieces. The wood pieces are joined together with adhesives under extreme heating and pressure conditions to form a wood board that is uniquely strong in all directions. Particleboards are less expensive than plywood or natural wood. To add further strength and durability to particleboards, they are often coated with melamine or finished with wood veneer.

Fiberboard

Wood fibre produced from mills and other construction sites is combined and glued together in a specific board shape using a synthetic resin-based adhesive, which results in a strong wood board that is moderately strong and resistant to breaking. Low-density fiberboard (LDF), medium-density fiberboard (MDF), and high-density fiberboard (HDF) are the common types of fiberboard.

MDF (Medium Density Fiberboard)

Medium-density fiberboard is both strong and affordable. It has good density and can be as strong as plywood. MDF is commonly used for building furniture parts such as drawers, and tables for office and dining. It is not water-resistant and not suitable to use outside, however, MDF has decent durability and strength and can be used the same as solid wood for a range of projects.

Veneer

Veneer is a thin layer of wood that is generally added to manufactured boards like particleboard or MDF to enhance their strength and make them more durable and resistant to moisture, termites, etc. It also helps give manufactured boards a more natural, wood-like finish.

Some other, lesser-known types of manufactured boards include blackboard, hardboard and insulation board.

Blockboard

Blockboard is generally used as a cost-effective alternative to plywood, especially for applications needing boards of higher thickness. It is formed by combining a solid timber core with two outer facing veneers such that their grain is at right angles and form a solid, strong product.

Hardboard

Hardboards are made from wood fibre, which is pressed between hot plates to produce large, thin grainless sheets that are generally used for making inexpensive furniture like cabinets.

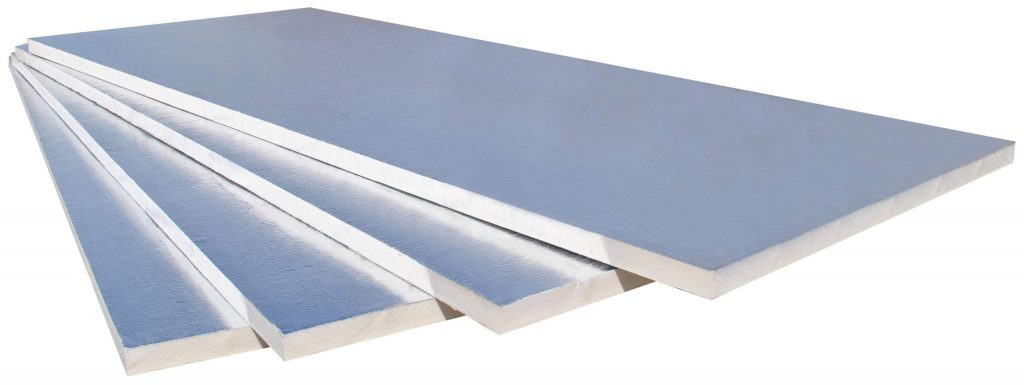

Insulation Board

Insulation board is a manufactured board that is primarily used on indoor walls for the purpose of providing insulation against heat and sound. It is made from wood pulp and is weak and with low density.

So, now that you know all about the different types of manufactured boards, are you ready to buy the best wood board for your project? Have questions or need help? Contact us at CameroonTimberExportSarl to enquire about the best wood timber for indoor/outdoor projects or to buy the best quality wood at the lowest price in the market. We deal in a wide variety of manufactured boards, including laminated chipboard, plywood, wood chips and more and deliver to all major countries in Asia, Europe, Africa and America.