Engineered wood is artificial wood that is made by using natural wood (softwoods and hardwoods) and a variety of additives like adhesives. Different types of engineered wood are considerably cheaper than natural wood because it is made from waste wood (coming out of sawmills) and rejected wood but can be equally strong or even better.

To increase its strength and durability, engineered wood is often treated through various processes. Also, these woods can be manufactured in custom sizes to fit specific requirements of certain premises.

Note: CameroonTimberExportSarl is a leading supplier and global exporter of top quality African timber sawn wood and logs with guaranteed on-time delivery. Contact us to enquire.

Benefits of Engineered Wood

Engineered wood has many benefits over natural wood timber, such as:

- These can be stronger than some natural wood species; Can have more durability and better insect resistance;

- Looks almost the same as natural wood;

- It comes in custom sizes and can be manufactured to fit any place;

- Engineered wood is less costly than natural hardwood;

- Suitable for a range of purposes, from flooring to furniture, construction, interior design and more;

- Engineered wood is sustainable because it is generally made from the waste parts of a tree that are generally rejected when making timber.

9 Different Types of Engineered Wood

Depending on quality, strength and design, different types of engineered wood are categorised as follows:

- Laminated Veneer Lumber (LVL)

- Laminated Strand Lumber (LSL)

- Oriented strand board (OSB)

- Plywood

- AB

- AC

- CDX

- High-density fiberboard (HDF)

- Medium-density fiberboard (MDF)

- Composite board

- Cross-laminated timber (CLT)

- I-Joists

1. Laminated Veneer Lumber (LVL)

LVL is made by compressing wood veneers together using resins and glues. This engineered wood is very strong and highly dense and can be used in a variety of projects, including framing. Veneers in the LVL wood are stacked such that grain is in the same direction, which is why it has a single strength axis and can take the load in one direction.

2. Laminated Strand Lumber (LSL)

This type of engineered wood is made by combining small wood strips – called strands – in a dense pattern such that the result is a high-quality, strong and dense wood product. LSL is primarily made by using wood fiber and resin. It can easily take heavy loads and is about 3 times costlier than natural wood because of the high demand.

3. Plywood

Plywood is a wood sheet that is made by combining thin layers of wood (plies) or veneer together using glue. Plywood is generally one of the most popular types of engineered wood and a common choice for builders. This composite wood is made by combing resin and fiber sheets together and has extraordinary strength and stability because of its cross-grain structure.

The two sides of plywood are made with veneers, which can be of different types depending on the quality. The common types of veneers used in plywood are A, B, C, D, and X, where A-grade veneer is of the highest quality and the D-grade is for the lowest quality, while X indicates plywoods that are suitable for external use.

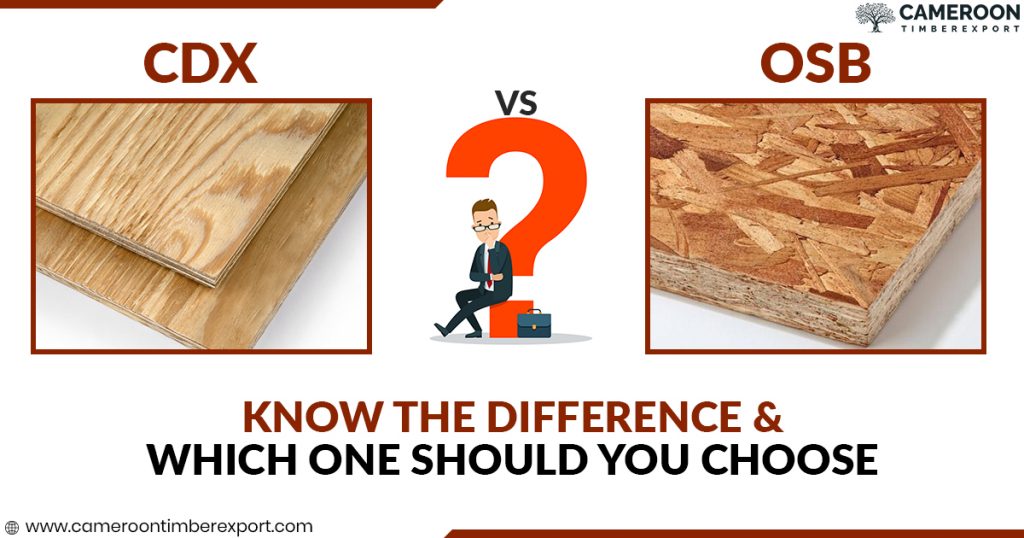

CDX plywoods, for instance, have C-grade veneer on one side and D-grade on the other side and are suitable for outdoor use.

4. Oriented Strand Board (OSB)

This is a type of wood sheet or board that is formed by compressing wood strands or flakes together with adhesives. OSB sheets are primarily used in flooring, roof decking and other load-bearing applications. OSBs can be further categorised into other types based on strength, moisture resistance, and whether or not the board is sanded.

5. High-Density Fiberboard (HDF)

Fiberwood is a type of engineered wood made using fiber and glue. Based on the density, it can be of different types, including HDF, MDF and LDF.

High-density fiberboard, or commonly known as hardboard, is made by combining wood pulp with glue in a densely packed structure. It is strong, hard and can be used in a variety of projects including for making curved items.

6. Medium-Density Fiberboard (MDF)

MDF is formed by combining fibers (made by breaking down hardwood and softwood pieces) with wax and resin into panels under high temperature and pressure. It is highly dense and can withstand moisture and insect attacks, depending on the quality.

7. Composite Board

Any wood that is formed by combining two different items is composite wood or board. MDF and OSB are popular examples. Composite engineers boards can have both wood fiber and plastic content and are sustainable and cost-effective.

8. Cross-Laminated Timber (CLT)

Cross-laminated timber is engineered wood made by combining the layers of solid sawn timber panels in a cross form using glue such that each layer is perpendicular to the next. The result is a stronger wood with a flexible design and excellent insulation capabilities.

9. I-Joists

I-joists are a special kind of engineered wood that is designed to take heavy loads. These are suitable to use in all kinds of building structures, especially in areas with heavy loads, including floors and roofs.

For all your timber needs for composite wood and engineered wood, contact CameroonTimberExportSarl to buy premium quality wood timber at the best price online with worldwide delivery.