Wood is generally the most favoured element for making pallets. Wood pallets are strong, attractive and can be used for a variety of applications.

However, choosing the right timber for making wood pallets can be more difficult than you think. You might need to consider a number of things and a variety of wood species in order to find that perfect timber for your pallets.

Here’s everything you need to know about the different types of wood used for making pallets:

What are Wood Pallets?

Wood pallets are made by placing several deckboards on a platform made by using three or found wooden stringers or supports.

Pallets are commonly used as a platform for holding goods. They are also sometimes used in construction and for firewood.

Materials Used to Create Wood Pallets

Wood is the most common material used for making pallets. These include softwoods and hardwoods. Many manufacturers also use a mix of different woods for making pallets.

Other than wood, paper, metal, and plastic are some other popular materials used for pallet manufacturing. Paper pallets are made from corrugated paper. aluminium, carbon steel, or stainless steel are the common choices for making metal pallets. High-density polyethylene (HDPE) and polyethylene terephthalate (PET) are commonly used for making plastic pallets.

How to Choose the Best Wood Type for Manufacturing Wood Pallets

Among the factors to be considered when choosing wood for pallets, quality and durability of the timber are the two most important things.

Hardwood is preferred over most other materials because of its natural strength and durability, which makes them perfect for manufacturing pallets. It is also a sustainable and eco-friendly option, especially when compared to non-biodegradable alternatives such as plastic and metal. Wood can be easily decomposed and is also generally cheaper (but not always).

Softwoods are also a good and cost-effective option for making high-quality pallets. They have the advantage of easy availability and lower price than hardwoods.

Here are the top factors to consider when choosing wood for pallets:

Strength: the strength of the wood is definitely an important factor in its selection for the construction of pallets. Because pallets are mostly used for load-bearing, they must be strong and sturdy.

Durability: Another factor to consider when choosing pallet wood is its durability and resistance to weather and insects, especially if you’re planning to use pallets in conditions where they might be exposed to weather and/or earth.

Weight: Pallets must be strong and durable but they should not be too heavy to handle.

Load-weight: The best type of wood for making pallets will also depend on external factors such as the amount or weight of the load you’re planning to put on the pallet. Since pallets are often used for carrying heavy loads in industries, the wood used for making such pallets must have a high density to avoid accidents.

Availability: Pallets can be made from a variety of wood types. The wood for pallets is also commonly selected based on the location where it is being made. Not all wood species are equally accessible in all parts of the world. So, a manufacturer can choose a timber he has higher or more affordable access to for making pallets.

Price: Price is another factor to affect the type of wood used for manufacturing pallets. The more easily available the wood, the cheaper it will be priced, which makes it an ideal choice for pallets for some.

Purpose or intended use: Finally, the type of wood you buy for making wood pallets will depend on where and how you plan to use it. Different applications demand different types of wood. For example, pallets intended for regular use can be made with low-density hardwoods or softwoods.

Oak and southern yellow pine are the most popular wood species used for constructing pallets.

Types of Wood for Pallets

There are the following three types of wood that can be used to make pallets:

- High-density hardwood

- Low-density hardwood

- Softwood

High-Density Hardwoods for Pallets

High-density hardwoods are hardwood species with high density or weight. These wood types are generally very hard and can be moderately to very durable depending on the species.

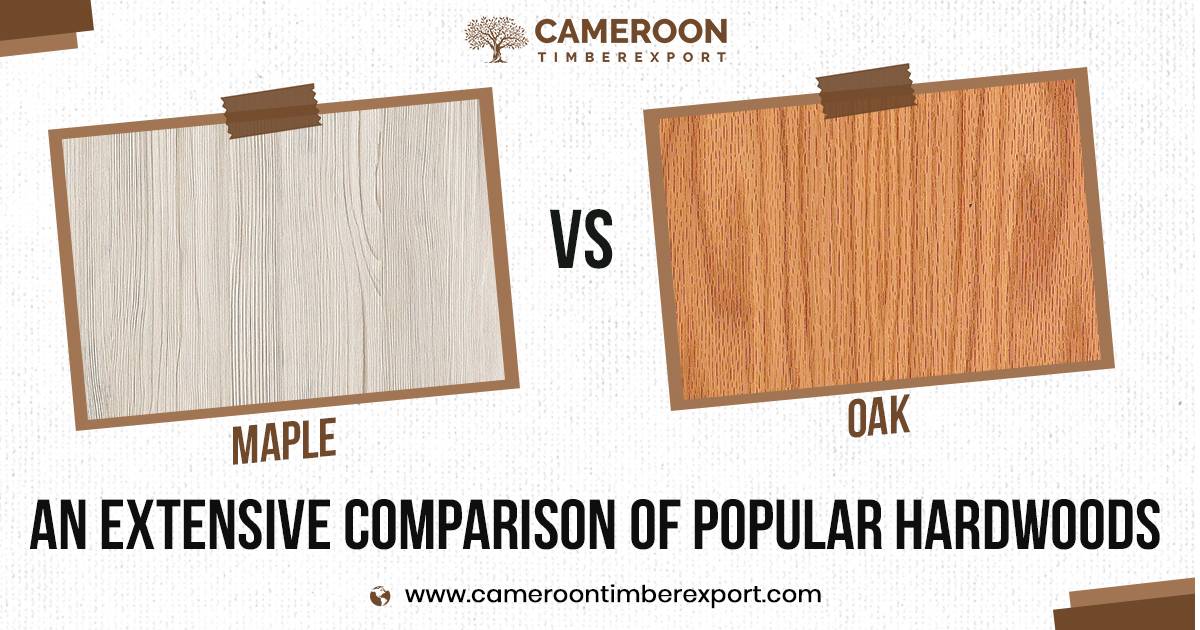

Examples of high-density hardwood species include Birch, Cherry, Ash, Beech, Yellow Birch, Oak, Maple, Elm, and Red Maple.

Low-Density Hardwoods for Pallets

Low-density hardwoods typically have lower density or weight than high-density hardwoods. These are softer and have low to moderate durability. But, they also cost less.

Examples of low-density hardwood options for pallets include Poplar, Willow, Walnut, Linden, and Aspen.

Softwood for Pallet Making

Softwoods are wood species that are obtained from conifer trees such as pine.

This type of wood is generally softer, less dense and less durable than hardwoods. Softwood species are used as a cost-effective and more easily available alternative to hardwoods for making pallets.

Some of the most popular types of softwood for pallet manufacturing are Cedar, Cypress, Hemlock, Spruce, Spruce, Pine, and Fir.

Softwoods are more easily available and economically priced than hardwoods, which is why many wooden pallet manufacturers choose them for their apparent advantage. Even though softwoods are less dense than hardwoods, they can be as durable and strong.

Some of the most popular types of pallet wood are as follows:

1. Oak

Oak, which is a hardwood, is one of the most popular wood choices for pallets. It is prized for its incredible strength and easy availability. Oak is used in construction, furniture making, flooring and several other applications. The leftover oak wood from the primary application such as furniture construction is generally used in pallet production.

Oak is a high-density hardwood that can be used for making strong and high-quality pallets to be used in heavy-duty industrial applications. Oak pallets can take heavy loads constantly without breaking or failing.

Though oak is widely available, buying or using it exclusively for making pallets would not be a cost-effective choice because of its higher cost than pine. This is why most of the oak used in pallets comes from leftover construction wood.

One benefit of using oak over softwoods for pallets is that even thin boards of oak can provide the same level of strength as heavier boards of softer woods such as pine.

2. Pine

Pine is the most popular softwood choice for pallet manufacturing. As a softwood with good durability, pine is also easy to work with and has a high strength-to-weight ratio, making it ideal for heavy-duty applications like construction and industrial pallets. Pine is also easier to find, costs less, and dries faster than most hardwoods. It can be treated with chemicals to make it resistant to a variety of pests and decay.

Pine pallets are clean and dry efficiently without any damage, which is why they’re particularly used in sensitive industries like food and pharmaceuticals. Pinewood pallets also don’t catch fungi or moulds easily. These pallets can be used for storing and carrying various products, including heavy items.

Other than oak and pine, the following wood species are also sometimes used for constructing pallets:

3. Poplar

Poplar is a type of hardwood that is rather soft, lightweight and easy to work with. It is moderately durable and has good strength and stability, which make it a popular choice for pallets intended for use in moderate-load applications. Also, poplar is easily available and is less expensive than many other hardwoods.

4. Birch

Birch is a strong and durable hardwood with a clean & smooth surface. It is commonly used for building pallets for industrial applications, particularly in the food or pharmaceutical industries, where having a flawless surface is important.

5. Beech

Beech is another popular hardwood used for pallets. It is a hard and heavy wood that can handle heavy loads and harsh treatment, making it an ideal choice for pallets for industrial and commercial applications, particularly for locations where the probability of wear and tear is high.

6. Maple

Maple is a hardwood famous for maple syrup. Hard maple such as rock maple or sugar maple is known for its strength and durability. It can resist moisture, insects, and damage from wear. It is suitable for constructing heavy-duty pallets that need to be used in high-traffic places and will last a long time.

7. Ash

Ash hardwood is strong, stable and flexible and is generally used for making pallets that may need to be flexible for applications where bending is required.

8. Mahogany

Mahogany is a hardwood that is prized for its high strength and durability. It is often used for making high-quality wood pallets intended for use in special projects where both the looks and strength of pallets are of concern.

Where to Buy the Best Wood for Pallets?

Whether you want to buy hardwood or softwood for pallets, Cameroon Timber Export SARL is your one-stop destination for high-quality, sustainable timber at wholesale price. We deal in a wide range of wood species, including pine, teak, poplar, mahogany, ash, and beech, all of which are suitable choices for building good quality wood pallets.

If you need help selecting the right wood for your project, call us to consult with one of our timber specialists.