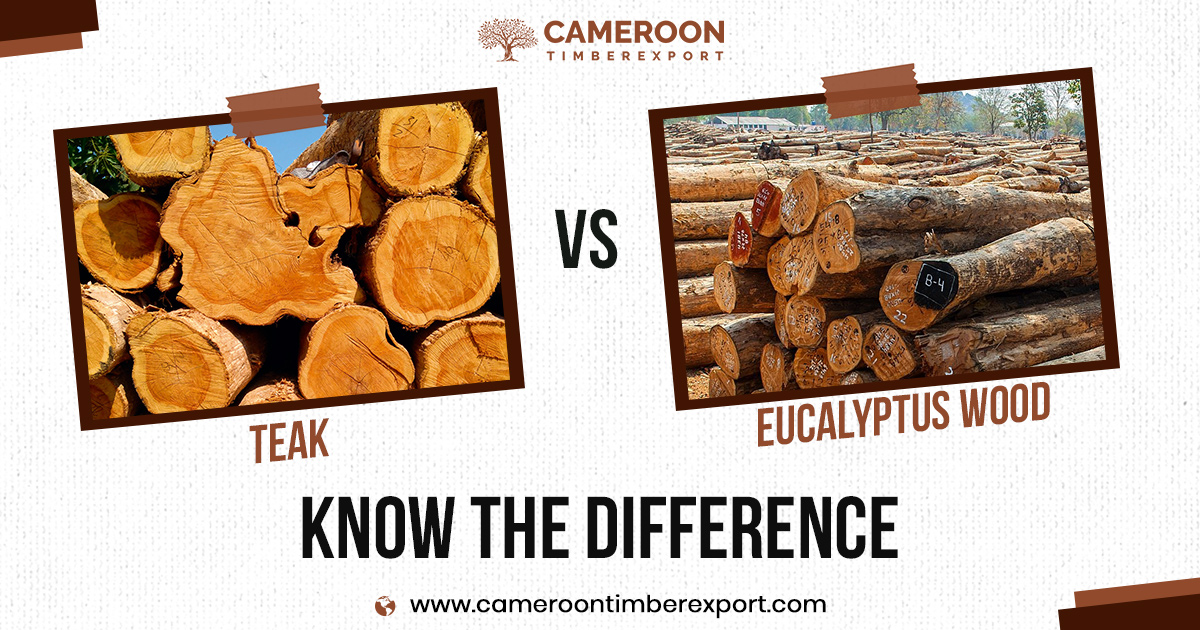

Teak and Eucalyptus are two of the most popular hardwood species used for outdoor projects such as decking and outdoor furniture.

Both Teak and Eucalyptus are strong and durable woods, but teak wood is superior in terms of durability and stability. Eucalyptus, on the other hand, is a hard but brittle wood that is prone to distortion and surface-checking.

Teak is usually hard to find and can be quite expensive depending on where you live. As one of the most durable and beautiful woods, teak has a very high demand in commercial applications. This is why woodworkers often look for alternatives that share similar properties to teak but are less expensive. Eucalyptus fits the bill.

If you’re planning to use Eucalyptus wood as an alternative to teak wood in your woodworking project, read here about a few very important things you should know about the difference between teak vs Eucalyptus timber.

What is Teak wood?

Teak is a hardwood native to India and Southeast Asia (Burma, Thailand, Lao). It’s one of the most popular hardwoods in the world known for its outstanding beauty, high durability, and natural resistance to rot and insects. The golden-brown colour of teak turns to a silverish hue over time, making teak furniture look more visually appealing as it ages.

Teak timber is particularly favoured for outdoor applications due to this wood’s incredible strength and durability. This includes decking and outdoor furniture. Teak has natural oils which make it resistant to water and insects. It doesn’t decay or rot easily even when in constant contact with water. Teak wood looks even more beautiful with the right finish.

Properties of Teak Wood:

Appearance: Golden or medium brown

Durability: Highly durable

Hardness (Janka): 1,070 lbf (4,740 N)

Average Dried Weight: 40.9 lbs/ft3 (655 kg/m3)

Workability: Fairly easy to work with

Cost: High

What is Eucalyptus Wood?

Eucalyptus is a hardwood found in Australia and some other regions around the globe. It is commonly used as a low-cost alternative to teak wood because of its easy availability and sustainability. Eucalyptus is almost as durable as teak and also very strong. It is moderately resistant to moisture and insects. The reddish-brown color of Eucalyptus is slightly lighter than teak. Also, the wood is less expensive.

Eucalyptus has a faster growth rate than teak and is considered a sustainable choice. It might be prone to warping and cracking if not handled properly. Sealing the wood ensures a long life for your Eucalyptus project. It is easy to work with, cut and paint and looks charming after a proper finish.

Eucalyptus wood specifications:

Appearance: Reddish-brown to cream

Durability: Fairly durable

Hardness (Janka): 3,730 lbf (16,590 N)

Average Dried Weight: 70.6 lbs/ft3 (1,130 kg/m3)

Workability: Fairly easy to work with

Cost: Cheaper than teak

Both teak and Eucalyptus are considered suitable for outdoor use, but Eucalyptus might need more frequent maintenance than teak.

Now that you know the basic details and properties of teak wood and Eucalyptus wood, let’s talk about the differences between the two.

Teak vs Eucalyptus

Both teak and Eucalyptus have their respective pros and cons, which we will discuss in detail here in terms of their respective properties, strength, appearance, durability, availability, price, and uses.

Appearance

Teak and Eucalyptus both are visually appealing woods. Teak has a warm, attractive, golden-brown hue that darkens over time. It has a fine grain and the natural oils of teak give it a classic elegance, which is why it is a preferred wood for luxury furniture.

Eucalyptus, on the other hand, features a lighter, reddish-brown colour with interlocking grain. The unique rustic charm is coupled with visible patterns on the surface of freshly sawn timber. Its appearance is more casual with a natural appeal, which makes it a favoured choice for outdoor projects or modern designs that reflect a natural aesthetic.

Strength & Durability

Teak is famous for its outstanding strength and durability. It is a very hard, dense wood with a tight grain structure and natural oils that make it remarkably resistant to rot, decay, and insects. Teak is well-protected against moisture and can withstand harsh weather conditions without decaying, making it a perfect choice for outdoor applications.

Eucalyptus is also a strong and dense wood but it is no match to teak in terms of durability. It may require additional treatment and need to be sealed to enhance its durability and resistance to insects and moisture when used in outdoor projects. The wood is perfect for indoor furniture or covered outdoor areas.

Workability

Teak and Eucalyptus offer distinct workability characteristics. Teak is generally easy to work with but its high oil and silica content can blunt tools. It is easy to cut and shape but glueing can be difficult due to oils. However, teak is exceptionally stable and can hold nails, screws and carvings very well, which makes it a superb choice for artwork.

Eucalyptus is moderately dense and hard, but it is easy to work with. It is particularly favoured for DIY projects due to its good workability. The wood is easier to cut and shape and doesn’t have a blunting effect like teak. It is not very stable though and drying can sometimes result in warping and cracking.

Lifespan

Teak is one of the best woods in terms of lifespan. The wood is known to last generations owing to its outstanding durability. With proper care, teak furniture and items can survive for decades, or even centuries. The wood is naturally resistant to decay and insects and doesn’t rot at all, which helps it live very long.

Eucalyptus is a durable wood but doesn’t have a life as long as teak. The wood is only moderately resistant to decay and insects. However, with proper treatment and sealing, it can be made to survive multiple decades.

Maintenance & Care

As a highly stable and durable wood, Teak requires fairly low maintenance. Like any other wood, it can be cleaned easily. Polishing every few years will ensure a very long life for your teak furniture. The golden-brown colour of teak naturally ages to an attractive silver-grey patina, which looks even more attractive to some. However, you can retain the original colour of teak by applying a good-quality stain.

Eucalyptus is not as durable as teak wood and requires more attention and care. It needs proper sealing to protect against moisture and UV rays when used outside. Moreover, it must be polished regularly to maintain its natural appearance. Without proper care, Eucalyptus can start deteriorating when exposed to outdoor environments.

Availability & Cost

Teak has always been a very popular wood with great demand, which is why the availability of teak wood has been a concern lately. Due to sustainability concerns, teak is now subject to stricter regulations, which has affected its availability and price. It is now among the most expensive woods in the world.

In contrast, Eucalyptus is more easily available due to its faster growth and average demand. It is also among the least expensive hardwoods. It’s often used as a cost-friendly alternative to teak.

Sustainability

Sustainability is definitely a concern when buying teak. Due to overharvesting over the years, teak is now subject to stricter regulations and can be difficult to find or import. Most of the teak you find comes from FSC-certified plantations, but illegally harvested teak is also quite common.

Eucalyptus is a sustainable and eco-friendly wood that is mostly derived from FSC-certified plantations and forests.

Uses

Teak and Eucalyptus both have a wide range of applications. Teak is a versatile wood owing to its high durability and timeless appearance, which make it suitable for various high-end applications, including indoor and outdoor furniture, cabinetry and construction. It is also perfect for outdoor and marine applications including boatbuilding, yacht decks, garden decks, and architectural elements.

Eucalyptus is an affordable and beautiful wood which can be used as an alternative to teak in some projects. Common uses include casual outdoor furniture, indoor furniture, decking, fencing, and paper production.

Teak vs Eucalyptus : Conclusion

As a woodworker, if you need to choose between teak and Eucalyptus and budget and availability are not an issue, then you must definitely go with teak, which is more beautiful and durable than Eucalyptus. However, if you are unable to find teak in your area or have a restricted budget, Eucalyptus is an almost equally great option, which looks awesome with a good finish.

Looking for a reliable teak wood supplier near you? Contact Cameroon Timber Export SARL to buy high-quality teak hardwood, timber or boards in custom sizes with doorstep delivery all over the world.