Timber logging refers to the process of harvesting (growing), sawing, and transporting trees for the purpose of commercial sale and use.

Logging is an ever-growing industry because people will always need wood to make paper, firewood, furniture, and buildings.

In the UK alone, billions of dollars worth of timber is traded every year. However, starting a timber business can be challenging, especially if you are unfamiliar with the process.

Here we explain the step-by-step process of starting a small timber business for beginners (with no industry knowledge or experience).

What Does a Timber Business Entail?

A timber logging business typically involves harvesting trees, cutting them down (sawing) or collecting fallen trees, and selling the logs to be processed at a sawmill.

Alternatively, you can start a sawmill or timber-selling business, which will involve purchasing logs from landowners, getting them sawn into processed timber, and selling them to customers or local merchants.

The Process of Starting A Timber Business

The process of starting a timber/logging business typically involves the following steps:

For Logging Business

- Market Research & Planning

- Purchasing a piece of forest or woodlands

- Staffing

- Planting trees for timber

- Felling trees

For Timber Processing & Selling Business

- Market Research & Planning

- Choosing the Product type, Range and Specialization

- Registering the Company

- Legal Requirements

- Staffing

- Setup for Timber Processing & Storage

- Transporting logs from the felling site to the sawmill

- Cutting logs into planks

- Drying the wood

- Wood treatment & storage

- Finding Customers

- Pricing and Profitability

If you have a passion for working with wood and want to use it to make a profit, starting a small timber business can be a perfect career choice for you.

This guide aims to provide you with a step-by-step approach to getting your timber business off the ground.

1. Market Research & Planning

Whether you’re planning to start a logging/harvesting business or a timber-selling venture or both, you’d need to research the market, including your target customers and potential competitors in order to plan ahead for the challenges that you might come across when starting a timber business.

Conducting thorough market research will also help you understand the demand, competition, and potential customers in your target area.

As a timber manufacturing/selling business, your target customers might include local woodworking businesses, construction companies, furniture manufacturers, etc.

You should contact them to understand their requirements and preferences. At the same time, you need to research the types of timber products that are in high demand.

Research the industry trends in terms of industry size, average annual growth, future forecasts, challenges, demand hotspots, etc.

Also, determine the estimated cost of starting a timber business in your area and expected profitability.

Study your competitors’ businesses to see what they’re selling and how you can make your business stand out.

Create a comprehensive timber business plan that outlines your goals, strategies, target market, financials, and marketing approach.

This plan will serve as a roadmap to guide you through the initial stages and ensure you are on the right path.

Also, include details about your pricing strategy, distribution channels, and future plans.

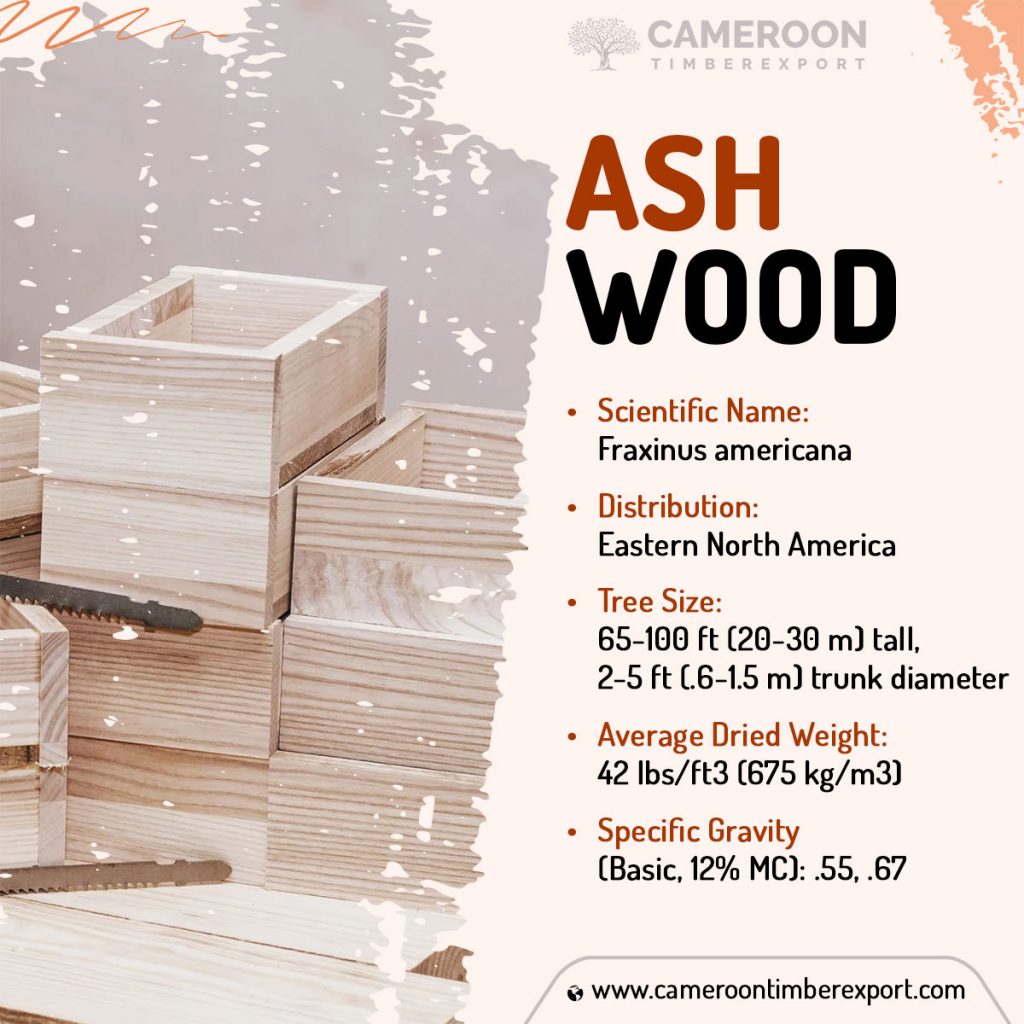

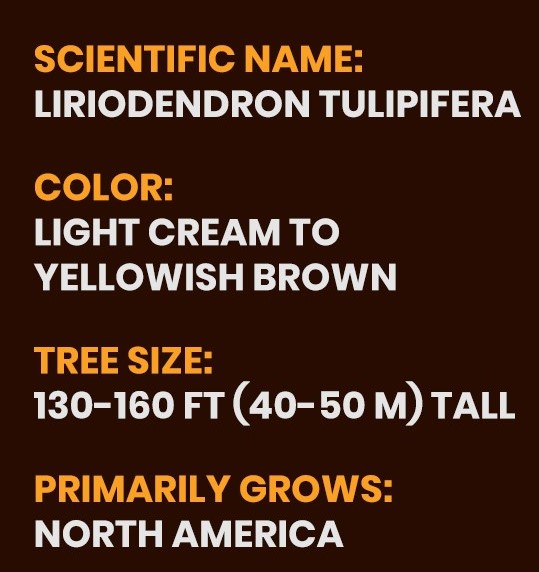

2. Choosing the Timber Type, Range and Specialization

After the initial research, you must have a good idea of the kind of timber products that are in high demand in your target region.

At this stage, you need to choose the timber species that you want to produce and/or sell.

Choosing the right product is very crucial. The timber species you’re selling must have a healthy demand and low competition or supply in your region. Then only you can make good profits.

Decide on the specific products you will sell based on market demand and your expertise. This could include wood logs, sawn lumber, timber products, custom furniture, etc.

Research the demand and trends in your target market to identify potential opportunities.

You can choose to only sell raw products, i.e. logs, or also sell processed wood, boards, planks, etc. Also, you can sell more than one product.

Some woods can be difficult to harvest or process, so you need to also consider the properties of the particular timber you’re planning to sell.

Continuously examine and update your product offering to adapt to changing customer needs.

3. Registering the Timber Company

Even if you’re not legally required to register when starting a small business, you must do it to ensure compliance and get the best out of government schemes for startups.

Familiarize yourself with the legal requirements for starting a timber business in your area. Consult with a legal professional or lawyer to understand the legal requirements when starting a timber business.

Register your business name, submit the necessary documents and fees, and obtain the permits and licenses to start your business.

Make sure that you get a compliance certificate for environmental regulations related to timber harvesting and processing.

Make sure to choose a unique but relevant name for your timber /logging business, preferably one that depicts your unique business values. Get your domain name registered as soon as you have a business name.

4. Staffing

You’ll, of course, need to hire people to help you with various things in your timber business. These may include forest consultants, farmers, woodworkers, administrative staff, financial consultants, etc.

You may alternatively consider hiring a timber consulting firm, which can help you with your legal & financial obligations and staffing needs when starting or running a timber business.

You need to plan ahead and analyze your workforce requirements based on the size of your business and the scale of operations.

Make sure to hire skilled & experienced employees who can contribute to the growth and success of your business.

At the initial stage of the business, you can also consider outsourcing certain tasks, such as consulting, accounting, and marketing, if it costs lower than hiring full-time staff.

5. Setup for Timber Processing & Storage

One of the most complex and expensive parts of starting a timber business would be to set up the wood processing unit.

This would include determining & arranging the location (facilities), equipment, machines, and systems for the business.

Some of the basic equipment and things you may need to run a timber business include a sawmill, tree-cutting machines & tools, safety equipment, a wood processing facility (mill), storage space, and transportation vehicles. You might also need to arrange kilns for drying wood.

You can, of course, consider leasing some or all of these things to cut costs at the early stage of your startup.

Ensure that your facilities are adequately designed to accommodate the wood production processes while adhering to safety regulations.

A sawmill or woodcutters are the most important components of your timber business. These can be moderate to expensive, depending on the type of machine you’re looking to buy.

You can always outsource wood cutting to an existing sawmill near you to save money.

Transporting logs from the felling site to the sawmill and delivering the final product

Depending on the scale of your business, you can consider purchasing or leasing a medium or big wood transportation truck for now. Alternatively, you can outsource transportation services.

Drying the wood

Drying the wood before storing or transporting it is a crucial stage in the timber processing business.

Natural wood contains moisture, which must be reduced to acceptable levels in order to make the wood suitable for commercial use.

The ideal moisture content in wood is as follows:

- For indoor uses: 6-8%

- Wood flooring: 6-9%

- Construction wood or outdoor uses: 9-14%

There are several methods of wood drying, but the two most popular wood drying methods are air drying and kiln drying.

Air drying of wood refers to allowing the timber to dry naturally by leaving it out in the open and letting the air flow through it, which helps reduce the moisture content in the wood.

This is an effective but time-consuming process. Drying wood with this method can take months or sometimes years.

The kiln drying method refers to the use of a special machine called a kiln in which the wood is subjected to specific temperature-pressure conditions in order to reduce its moisture content to optimal levels. This method is more effective and faster than air drying.

Wood treatment & storage

Wood is also often treated with preservatives to enhance its strength, durability & other physical properties. This is usually done at the mill itself.

You also need to have proper facilities for storing final timber in a dry and covered place that is protected from excessive moisture, heat, etc.

6. Finding Suppliers & Customers

Depending on the kind of timber business you’re starting (manufacturing/processing/selling), you need to find reliable suppliers for raw materials such as plant seeds, fresh wood logs, etc.

At the same time, you need to establish a system for finding and connecting with potential customers.

To start with, identify reliable suppliers of timber in your region, who can deliver high-quality wood at a reasonable price and with consistency.

Establish partnerships with them. Make certain that the timber you buy comes from sustainable sources and is in accordance with responsible forestry practices and laws of your region.

Building & maintaining strong relationships with your suppliers is crucial for ensuring a consistent supply of high-quality timber.

Always establish agreements or contracts with suppliers to maintain transparency in pricing, partnership rules, and delivery schedules.

One of the best or easiest ways for a timber business to find new customers is online marketing.

With 7 out of 10 customers searching online for products or services, you could effectively find and reach many potential timber buyers in your location by improving your online presence to ensure your business is visible to potential customers searching online.

Similarly, you can use the internet to find suppliers too for your timber business.

7. Pricing and Profitability

Determining competitive pricing for your timber products is important to attract customers.

Consider factors such as raw material costs, labour, processing & storage expenses, transportation costs, and profit margins. Research local market and competitor rates and adjust your prices accordingly.

You might have to compromise on profit margins in the starting days in order to create a demand for your product in the market and attract customers. Other than that, you can consider offering discounts for bulk orders.

Conclusion

Starting a small timber/logging business requires careful planning, market research, and the need to consider and arrange for the crucial parts of a successful timber business.

By following the steps mentioned here and continuously adapting to the changing needs of your target market, you can establish a successful and sustainable timber business.

If you need professional help setting up your timber logging business or need to consult with a woodworking expert, contact CameroonTimberExportSARL today to talk to one of our specialists.