Water resistant wood or waterproof timber refers to wood that has basic or advanced water resistant properties. In other words, water resistant timber can survive in normal rainy conditions without going bad. This type of wood is particularly useful for making outdoor furniture, boats, ships, decks, and outdoor flooring.

Just because rain or excess water can harm wood doesn’t mean you cannot or should not use wood for outdoor furniture and similar purposes. This is where timber waterproofing comes in.

While some timber species useful for outdoor use are naturally water resistant, others can be treated to add waterproofing abilities to them.

Factors To Consider When Selecting Water Resistant Timber

Moisture Content

The moisture content in wood is an important factor to consider. Normally, wood has about 20-30% moisture content, which can increase when the wood is continuously exposed to moisture or rain without prior treatment.

Oxygen Content

The higher the oxygen content in the wood, the higher will be the probability for it to rot in the presence of moisture.

Maintenance Needs

Some timber species need more maintenance compared to others and can start rotting in the constant presence of water if not maintained properly.

Wood Species

As we mentioned before, some wood species are more water resistant than others. So, select your wood wisely and only after considering all your requirements.

Top Waterproof Timber Species

Following are some of the best timber species that are naturally resistant to water and moisture and are suitable for rainy places.

1. Afrormosia

Afrormosia is an Africa-native hardwood that is commonly used as an alternative to teak, mainly because of its outstanding durability and resistant capabilities. The timber is widely used for making outdoor flooring, patio furniture, boats, etc. And it costs nearly half the price of teak.

2. Teak

Teak Wood is one of the most popular and widely used hardwood species. It also has extraordinary moisture resistance, which makes it the preferred choice for outdoor furniture, boats and flooring. However, the price is generally higher than alternatives.

3. Cedar

Cedar also has decent wood resistance. However, cedar has many varieties, with different cedar species having different resistance capabilities.

4. Mahogany

Natural mahogany is very durable and has good resistance to moisture and rot. It is usable both indoors and out.

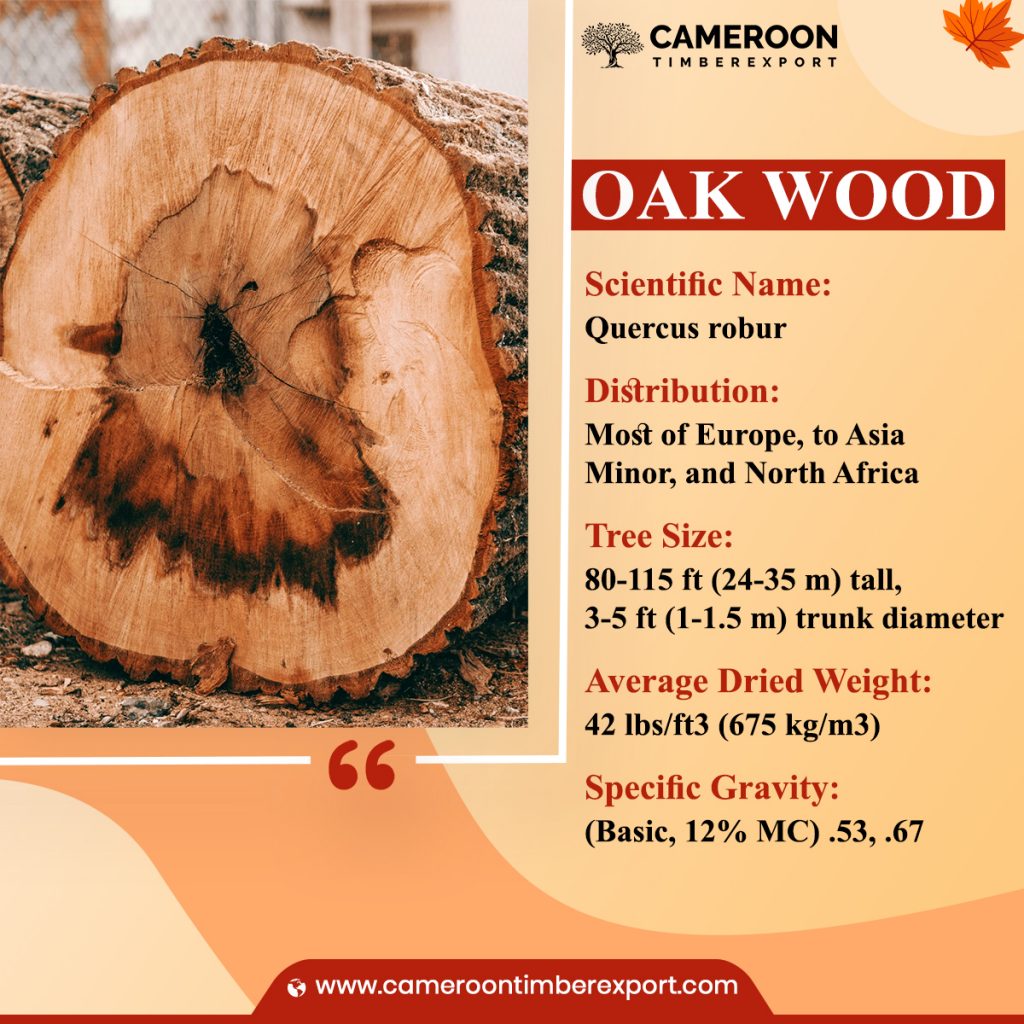

5. Oak

Some species of oak, including white oak, are rated as very durable and show outstanding resistance to water. This is why they are widely used for boatbuilding.

6. Redwood

Redwood is primarily used for making furniture that shows great durability and is particularly attractive in appearance.

How To Make Wood Waterproof (Timber Waterproofing Methods)

Wood treatment is the process of externally treating the timber to enhance its natural properties, including water resistance, rot resistance, strength, and durability. The following four methods are known to help increase the water resistance capability of wood.

Waterproof Staining

Staining refers to the process of using stains to color the wood to make it waterproof to some extent. Waterproofing stains are usually made by combining a sealing agent with the dye. Depending on the type and quality of stain, it can make the wood waterproof for up to many years.

Waterproofing Sealing

In the sealing process, sealants are used instead of stains. Sealing only provides resistance to moisture but not so much for heavy water exposure or rains.

Waterproofing Finishing

Finishing is another commonly used method to provide water protection to wood intended for outdoor furniture and floors. This involves finishing the wood using a specialised coloring agent that adds both a new glossy layer to the wood as well as enhances its resistance to water and rot.

Waterproofing Stabilizers

Wood Stabilizers work differently than finish or stain. They do not make the wood durable on the outside but react chemically with the alkali inside the wood in order to make the wood more waterproof. Also, it is organic and, therefore, safe for humans.

How To Protect The Wood From Water/Moisture Damage?

Besides staining or sealing the wood, there are a number of things you can do to ensure a long life for your patio furniture and outdoor flooring. These include:

Regular Maintenance: Even though the outdoor furniture and decks are usually made with water-resistance wood, taking good care of them is important to ensure a long life. Besides regular cleaning, you need to keep the moisture away from wood. If the furniture has become wet, clean or wipe it immediately. If there are open pores in the wood, use paint or polish to close them.

Use covers: Using a plastic cover on your outdoor furniture and wood objects, especially during rain and extreme heat, is another good way to protect the timber from damage and ensure a long life.

To buy the best quality water and rot resistant wood, timber and slabs at the lowest price online with doorstep delivery to your location, contact CameroonTimberExportSARL.