Engineered wood is increasingly becoming the best alternative to solid wood for those who either prefer a more attractive, customisable option or want a cheaper option for wooden flooring in their homes and offices. There are many engineered wood flooring advantages and disadvantages while using. We’ll discuss them in detail here. But, first things first.

What is Engineered wood?

Engineered wood is an artificial wood that is manufactured using solid wood and other products. It can also be understood as a layered wood product that contains solid wood along with a highly durable plywood core.

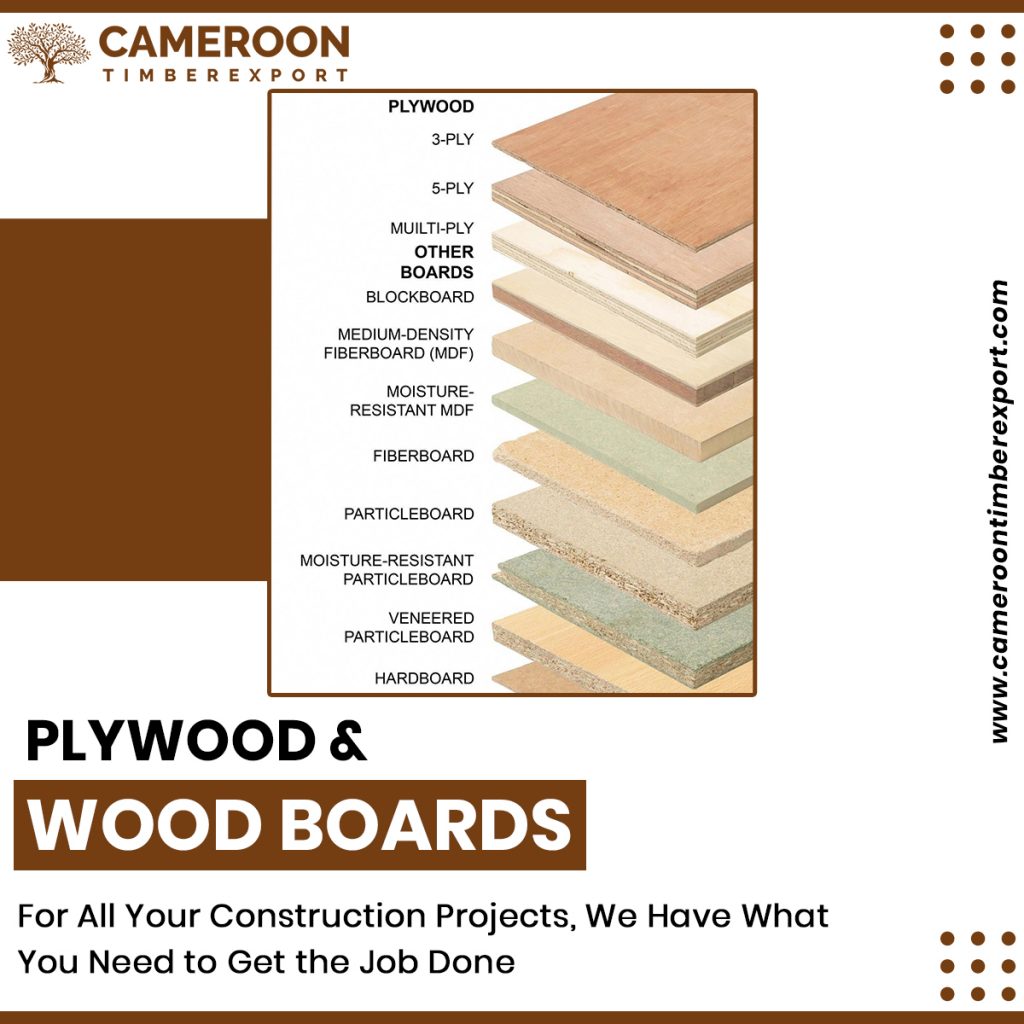

In some cases, engineered wood is ever stronger and more durable than some solid woods. There are different types of engineered wood, including plywood, medium density fiberboard (MDF), low density fiberboard, oriented strand board (OSB), etc. Plywood is among the most durable and popular types of engineered wood.

Engineered Wood for Flooring

The use of wood for flooring is not new. For many decades, even centuries, people have been using wooden flooring in their homes and workplaces. Wooden floorings are not only attractive but also they can give your place a natural, scenic feel. Also, many people find wooden flooring amazing to walk on.

Engineered wood flooring can be of many types, based on the type and quality of materials used. The layers in a manufactured wood are glued together at a 90° angle and under specific heating and pressure conditions to achieve the desired product.

For whatever reason you are planning to use engineered wood flooring, here’s a detailed discussion on engineered wood flooring advantages and disadvantages for you to know before installing the floor.

Like any other type of flooring, engineered wood floors have some pros and cons of their own. Of course, it is not as good as real solid wood, but it’s the second-best.

Advantages of Engineered Wood Flooring

1. Looks Like Wood

The biggest advantage of using engineered wood for flooring is that your floors will give the appearance of real, solid wood at a much lower cost. Besides that, the engineered wood flooring is also more durable.

2. No Expansion or Shrinkage like Wood

While real wood might shrink and expand under certain temperature conditions, engineered wood has no such problem; it always maintains its size and shape.

3. Easy, Quick & Cheap Installation

Engineered wood flooring is easy to install and take care of. Also, the installation will cost much less as compared to traditional flooring because of the reduced labour needs. Homeowners with basic woodworking knowledge can install their own wood flooring.

4. Save Money

One of the biggest advantage of using engineered wood in place of solid wood is, of course, the price. Because many of the popular wood species are high in demand and limited in supply, they can be very costly to buy. Some of the rare wood species like African Blackwood, Brazilian Walnut, Ebony, etc. are really pricey and simply not affordable for everyone. (Contact Cameroontimberexportsarl for wholesale prices of popular hardwoods).

Engineered wood, though not as good as solid wood, can be equally great in appearance and properties. The thing to note is that engineered wood flooring costs much less than solid wood flooring.

5. Can be Polished and Re-Finished

It is easy to refinish or polish engineered wood flooring as and when needed. And because it is easy, you can do it yourself without needing an expert. This is why engineered wood is easy and inexpensive to maintain.

6. Strong and Durable

Engineered wood can be strong and very durable, depending on the type. Plywoods, for example, are available in many grades based on strength and durability. Some of them are even resistant to fire and a variety of natural and commercial environments. Some engineered wood flooring will easily last for 20-30 years.

Other benefits of engineered wood flooring include easy availability, low price, safe and non-toxic, among others.

Disadvantages of Engineered Wood Flooring

There are some limitations as well of using engineered wood for flooring in homes and offices, such as:

1. Lower Quality Than Real Wood

Of course, manufactured wood is not always as good as real wood, which is why one should only buy engineered wood from a trusted supplier like CameroonTimberExportSarl.

2. Too Thin Top Layer

The top layer of engineered wood flooring is made of solid wood. The thicker and stronger the top layer, the better the wood flooring. However, some low-quality flooring will have a very thin top layer with limited opportunities for refinishing and sanding.

3. Fading in Exterior Use

Another disadvantage of engineered wood flooring is when used outside will eventually start fading in constant exposure to sun, heat and weather conditions.

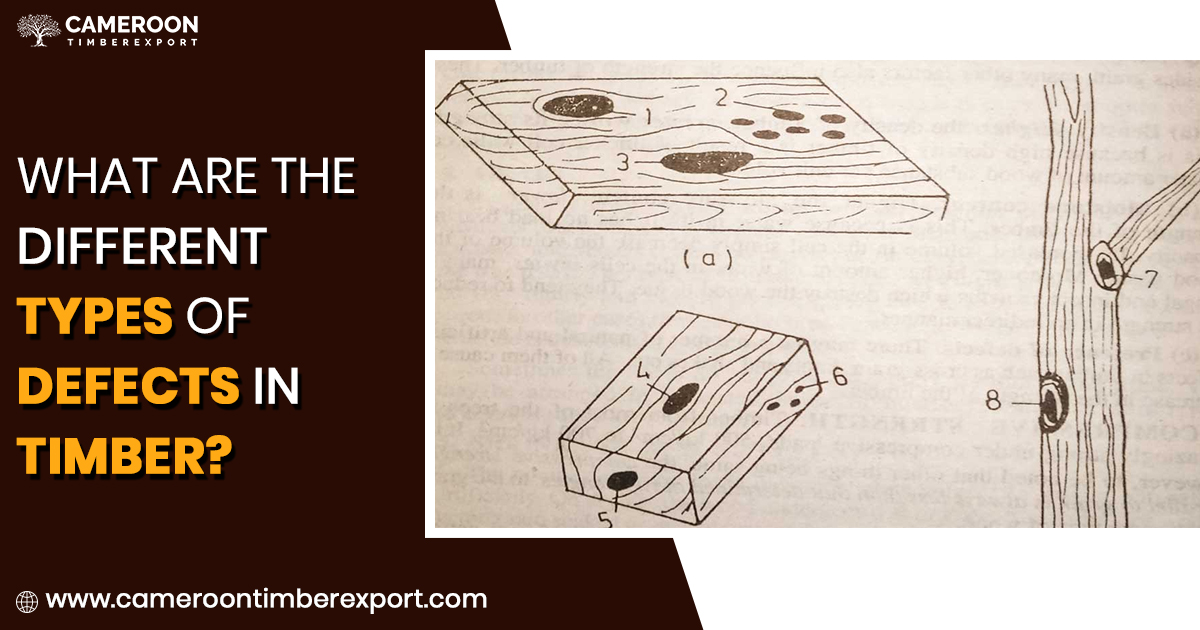

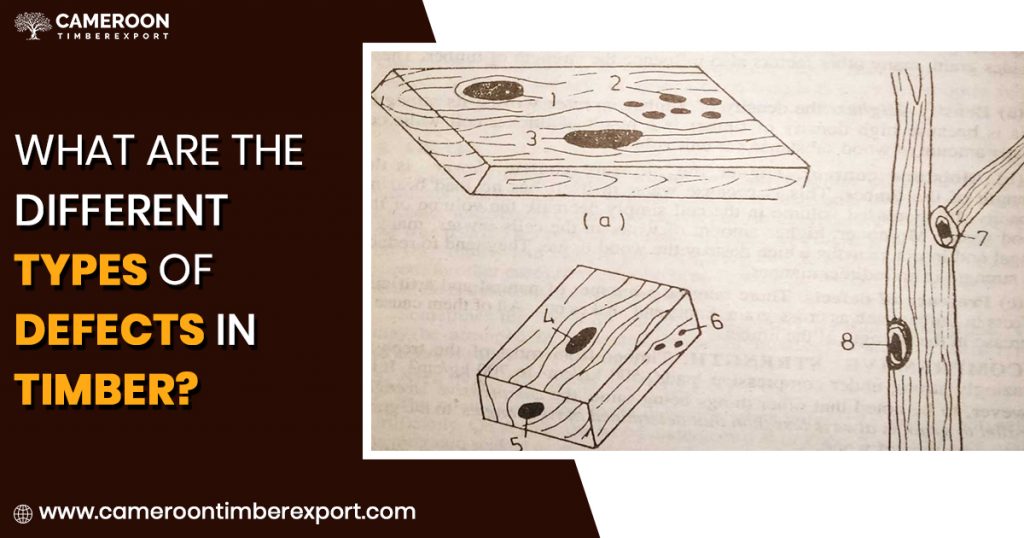

4. Prone to Termite Attack

Low-quality engineered wood can be easily infected by termites, especially if it is not pre-treated. If the core wood has excess moisture, the probability of termite attack is even higher.

5. Not Water Resistant

Not all engineered woods are water-resistant. In fact, many of them will be instantly affected by water and can have significant damage in no time. That’s why it’s important to choose high-quality engineered wood flooring that is also water-resistant.

Conclusion

In the end, after a detailed discussion on engineered wood flooring advantages and disadvantages, we discovered that a engineered wood makes the best alternative to solid wood for flooring. It is cheaper, easier to use and maintain and can have equally great strength and durability as real wood. However, one must choose engineered wood carefully because there are so many varieties and grades available in the market.

Need help choosing the right wood for your flooring project? Contact CameroonTimberExportSarl to explore our high-quality timber and engineered wood options and get the best price in the market with doorstep delivery anywhere in the world. Call us today +237 671 77 6559 to know more.