What is the Best Timber for Outdoor Use?

When looking to buy wood for outdoor projects such as outdoor furniture or flooring, choosing the right timber is crucial. The timber wood resistant to water, moisture, decay, insect and rot is considered as one of the best wood for outdoor usage. The outdoor wood must also be strong and dense enough. In this article, we will discuss the process of choosing the right wood for outdoor furniture as well as top timber species for outdoor use.

CameroonTimberExportSarl is a top supplier of the best quality African timber in a wide range of species suitable for both indoor and outdoor projects. We export timber to all major countries in the world. Contact us for a quote.

How to Choose the Right Timber for Outdoor Use

Choosing the right outdoor timber can be troublesome, especially since there are so many options to choose from. Even though the options for natural outdoor timber are limited, there are many timber species that do well for outdoor projects once treated with pressure (pressure treatment) or chemicals (chemical treatment).

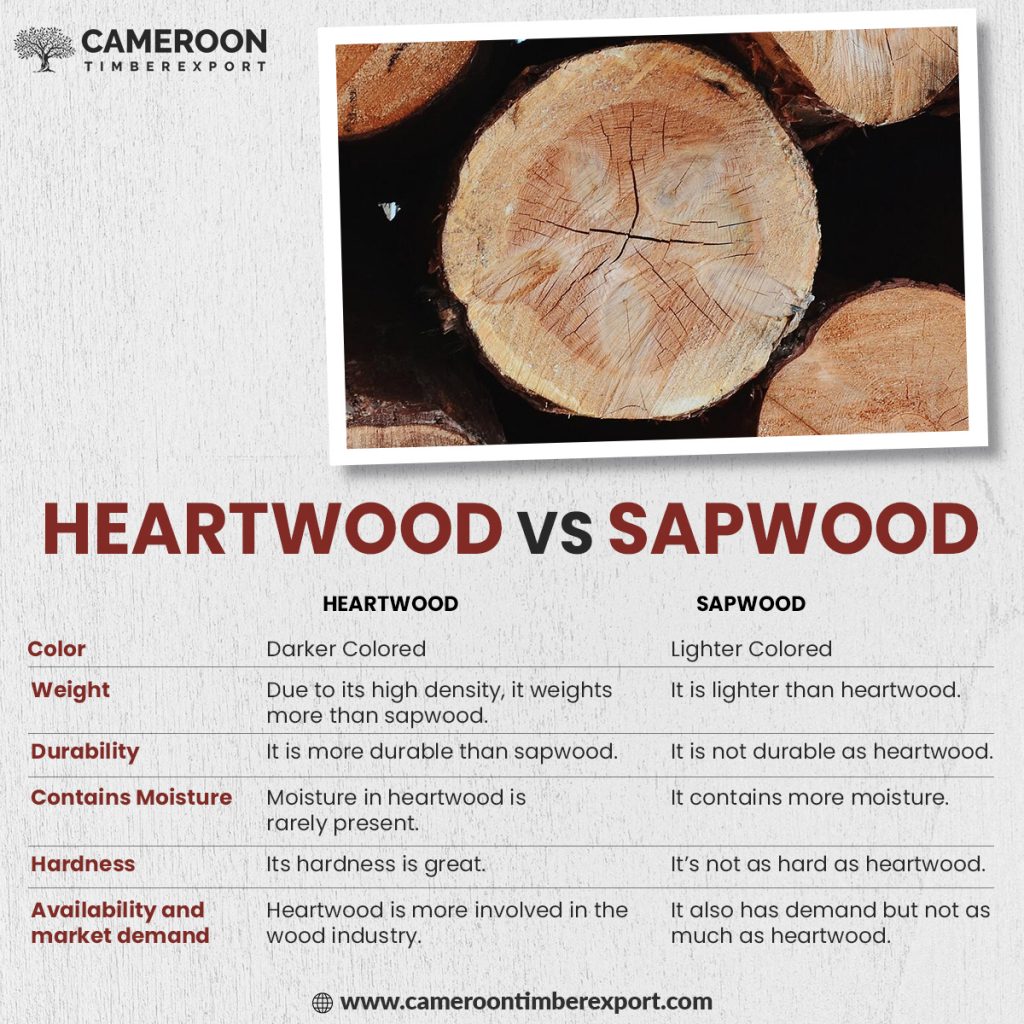

It’s also important to note that all timber woods can be broadly categorised into two types: hardwood and softwood. So, it’s crucial to understand the difference between these two types of wood.

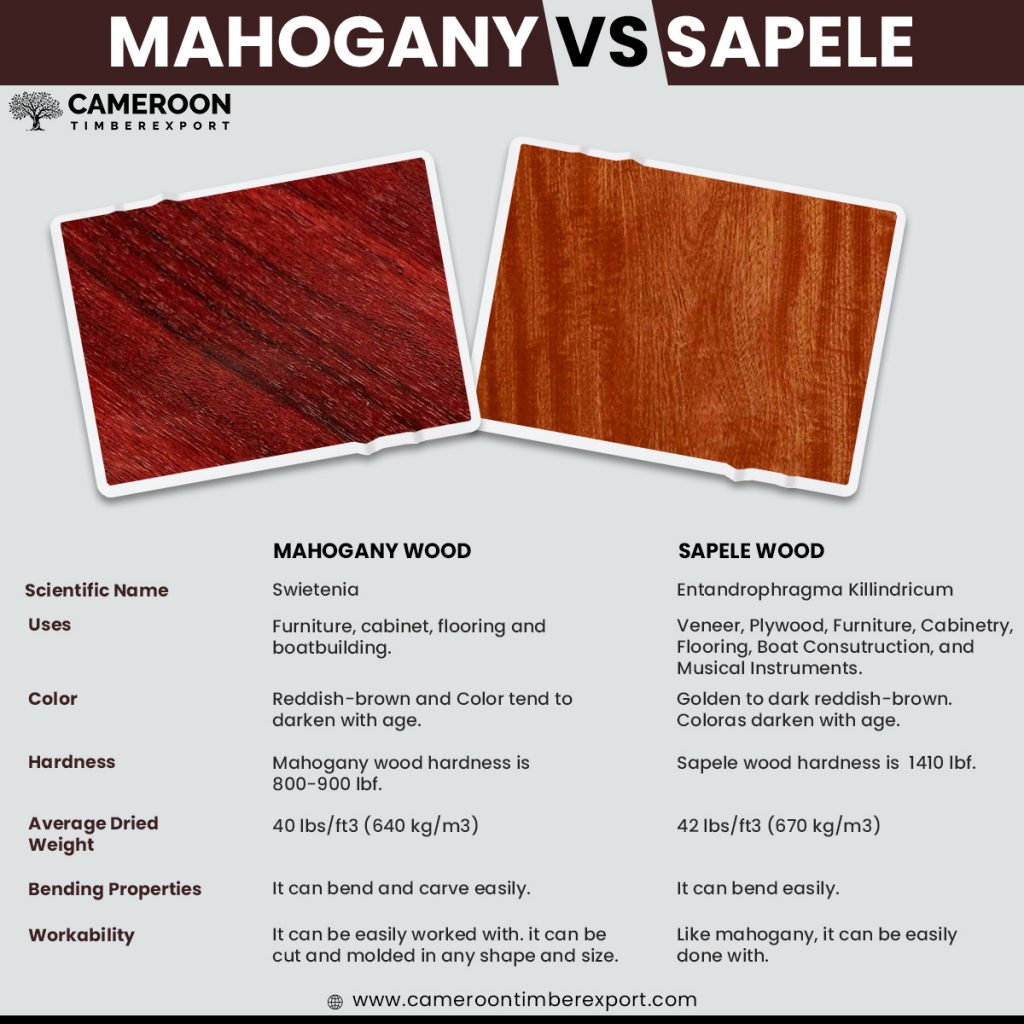

Hardwood is procured from angiosperm trees. Since they generally have a complex structure, hardwoods are generally harder than softwoods. Some of the common types of hardwood include oak, walnut, ash, mahogany, and maple.

Softwood is the wood produced by coniferous trees. Their cell structure is less dense, which makes them softer than hardwoods, but this isn’t always the case, as some softwoods are stronger and harder than some hardwoods. The growth period of softwood trees is generally shorter than that of hardwood trees. Pine, fir, cedar, redwood, etc. are the most popular types of softwood.

Best Timber Species for Outdoor Projects

Pine

Pine is a softwood that shows remarkable resistance features after treating it with chemicals. Treated pine is resistant to decay and insects, which makes it ideal for outdoor woodworking projects. Some of the common outdoor uses of pinewood include decking, flooring, outdoor furniture, cladding, posts, and poles. Treated pine is also easy to shape, paint and stain and is widely used for making curved and turned objects.

Pine is also easily available and comparatively affordable. Now you can buy Pine sawn timber directly from CameroonTimberExportSarl at the best price online and get doorstep delivery anywhere in the world.

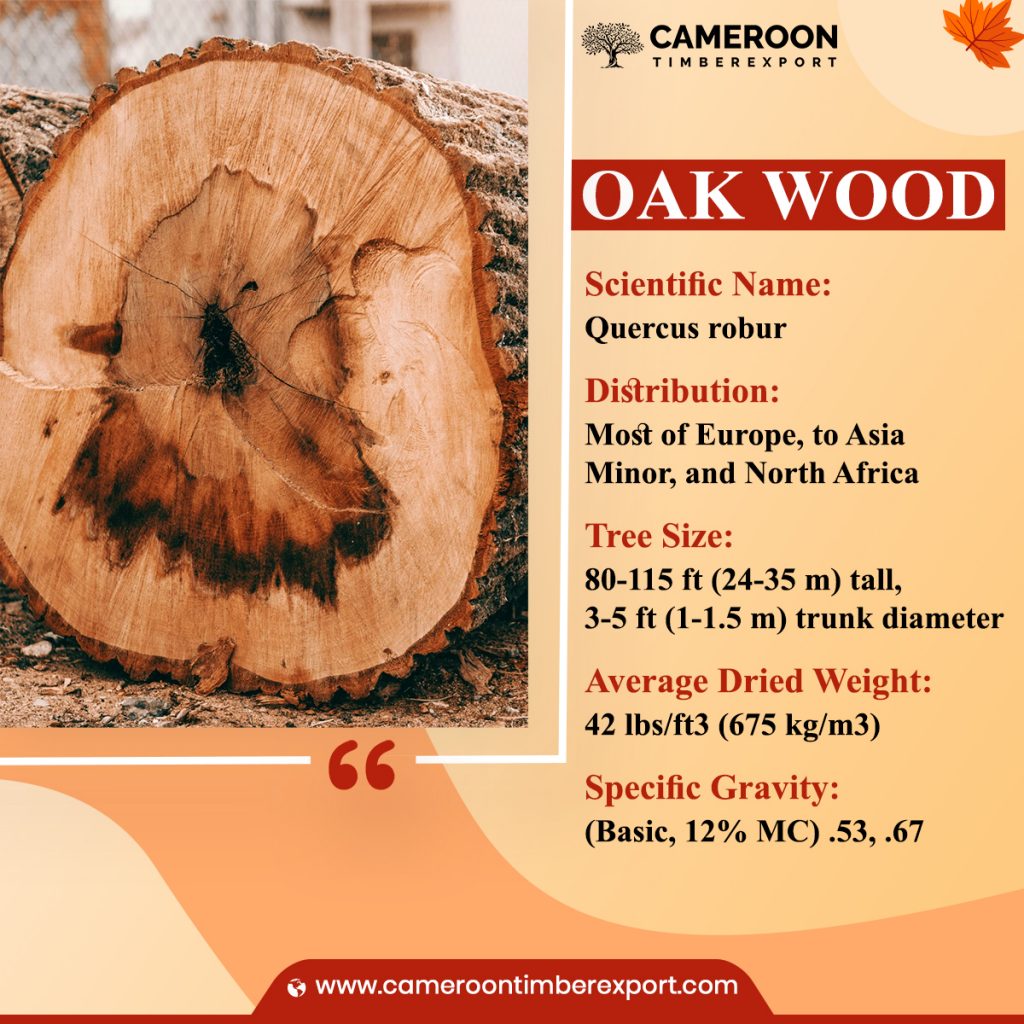

White Oak

White oak is another popular wood for outdoor projects. It’s a naturally dense wood and is much less porous than red oak. It’s super strong and the heartwood has good resistance to moisture and decay. White oak is easy to stain and work with. The common uses of this wood are furniture making, flooring, cabinets, and boatbuilding.

Merbau

Merbau is one of the primary choices for building outdoor furniture and wood items, mainly because of its excellent strength and durability characteristics. The Merbau timber also has good resistance to termite and lyctid borers, which makes it ideal for the places where these pests are common. Merbau heartwood is orange-brown in color and looks very attractive.

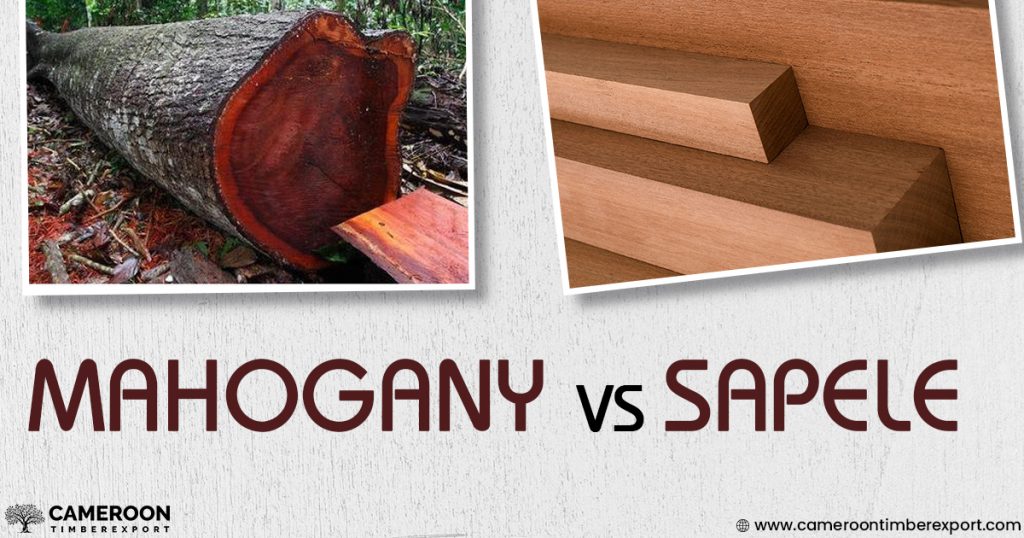

Mahogany

Mahogany is a widely popular timber for furniture making. It’s rather an expensive wood and is generally used for making high-quality, premium furniture. Mahogany wood cuts, stains, and finishes well. African Mahogany Wood is the best in terms of strength and durability. It has decent resistance to insects and termites. Buy top quality Mahogany at the best price online from CameroonTimberExportSarl.

Teak

Though teak is a rare wood species only available in certain locations, you can still manage to buy teak in small quantities from famous manufacturers including CameroonTimberExportSarl. The use of teak in a variety of woodworking projects, ranges from furniture making to boatbuilding and other craft-centric projects.

Ipe

Ipe wood is usually compared to walnut and ironwood because of its extraordinary strength and durability. It’s furniture can easily last for decades and depicts good resistance to warping, cracking, denting, and decomposition.

The use of rot-proof composites for outdoor projects is also very common nowadays.

Buy Quality Timber for Outdoor Furniture

CameroonTimberExportSarl is a leading supplier of the highest quality timber for outdoor furniture and a range of woodworking projects. We are the No.1 supplier of timber and wood logs to merchants in multiple countries, including Malaysia, UAE, Saudi Arabia, Australia, Canada, and others. Our timber products are sustainably sourced and carefully produced to ensure the best quality. Contact us today to enquire about timber availability and price.