Ash is a popular American hardwood found and used in all parts of the US and around the world. It’s a strong hardwood timber that is prized for its ease of work, shock resistance, wide availability, and inexpensive rates. Ash has many varieties, with white ash and black ash being the most popular two types. Here’s everything you need to know about Ash wood , its properties, uses and types.

About Us: For more than 30 years now, CameroonTimberExportSARL has been supplying and exporting the best quality timber products and hardwoods to our clients all over the world. We have immense experience in the wood industry and expert woodworkers in our team to help you find the perfect wood for your next project. Feel free to call us or Whatsapp.

About Ash Wood

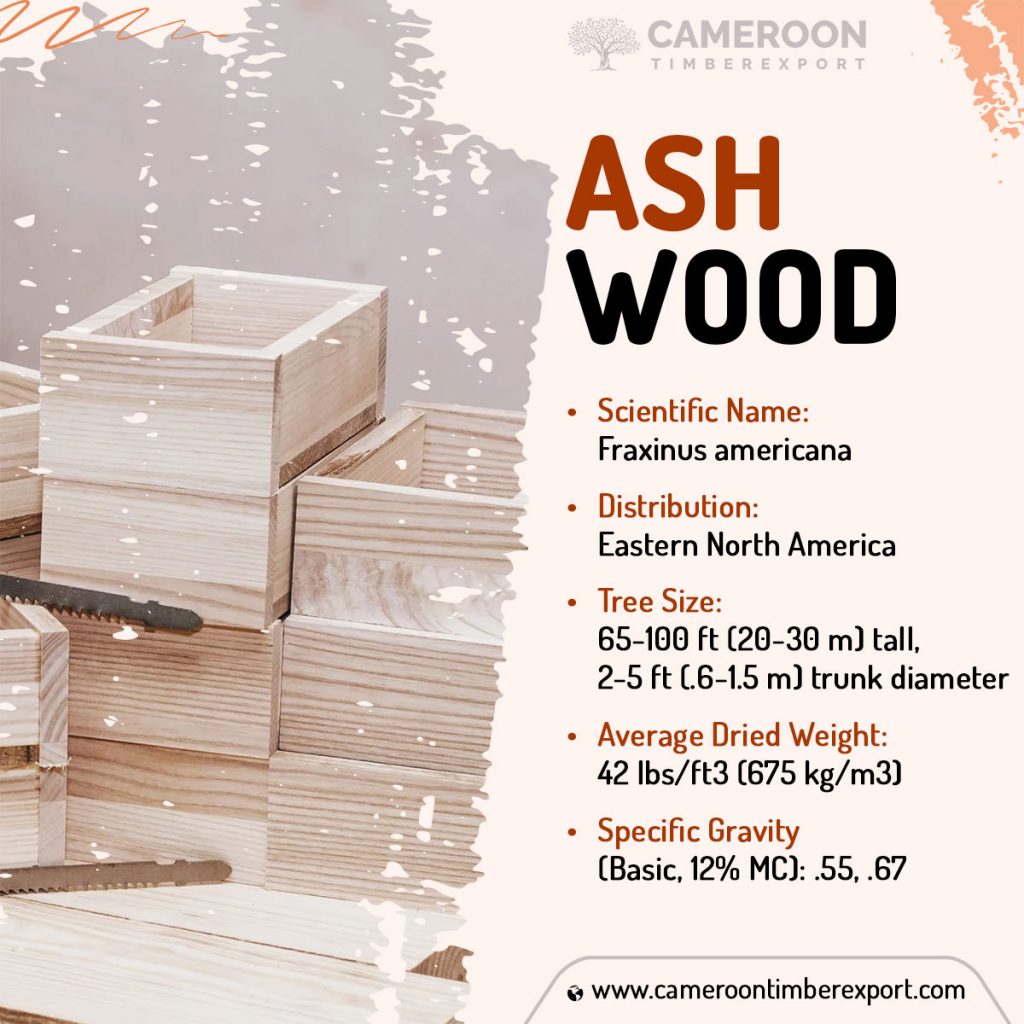

Ash or American White Ash is a hardwood primarily sourced from Eastern North America. Ash trees are about 65-100 ft (20-30 m) tall and have a 2-5 ft (.6-1.5 m) trunk diameter. The average dried weight of the wood is 675 kg/m3 and it has a 1,320 lbf (5,870 N) Janka rating. Ash is a hard, strong, heavy and dense wood.

Besides being one of the strongest and very dense hardwoods, Ash is also almost completely shock-resistant, which makes it suitable for heavy

Ash Wood Properties

Appearance: The heartwood of ash is light to medium brown, and the sapwood is light brown and generally very wide. The texture is medium to coarse and the grain is usually straight, though curly or figured lumber is not uncommon.

The colour of ash is lighter than oak but the texture is similar. Ash can look strikingly similar to oak when stained.

Durability: It’s a strong and dense wood that is smooth to the touch. However, ash is almost perishable in terms of durability and is not resistant to insect attack, though some durability against decay can be seen.

Workability: Ash is generally easy to work with both machine and hand tools. It glues, polishes, and stains well. Steam bending also has good results.

Ash is often used as a cheaper alternative to oak and a more attractive alternative to beechwood, all of which share similar properties. Despite being very dense, ash is lighter in weight compared to oak.

White Ash Vs Black Ash:

White ash has a lighter hardwood and the growth rings are wider spaced compared to black ash, which has slightly darker heartwood and closely placed growth rings. Both species are non-durable.

Ash Wood Price & Availability

Ash is one of the lowest-priced utility timbers available in the US. It is widely available and can be easily sourced all around the world at a low or moderate price, moreover ash is less expensive than oak but equally valuable.

Uses

Ash is prized for its notable strength and shock resistance. Historically, it was used for making shafts for spears. In modern times, ash is being used for everything from flooring and furniture to boxes, crates, baseball bats, tool handles, millwork, turned objects, and specialty items.

Because of its excellent shock resistance capabilities, ash is the most common hardwood used for making handles for shovels, hammers and other tools. The wood absorbs most of the shock caused by the impact when using these tools.

Ashwood is also widely used for making sporting equipment, particular bats for cricket, bows, and baseball bats. Kitchen utensils, such as knives and ladles are also found made with ash. Ash timber is used for furniture making and is equally good as oak. It is also commonly used in the construction of staircases, timber frames, treads, and moulding. Because of its bending properties, ash is also suitable for making bowls and other turned objects.

Ash, though, is poorly resistant to decay and insects and is not commonly used for outdoor applications. Ideally, it should not be in constant contact with the ground or it will start decaying.

Types/Species

Ash has many types and species and also some look-alikes, the most common of which are as follows:

- White Ash(Fraxinus Americana)

- Black Ash (Fraxinus nigra) – darker than the white ash, it is soft with an 850 lbf Janka rating and is used for making tool handles, boxes, flooring, baskets, and electric guitars.

- Blue Ash (Fraxinus quadrangulate) – Grows in the midwestern region of the United States. The inner bark turns blue when exposed to air, hence the name. It is hard and strong and is used for baseball bats, flooring, and tool handles.

- Green Ash (Fraxinus pennsylvanica) – It is moderately hard and easy to work with, found in eastern and central North America.

- Pumpkin Ash (Fraxinus profunda) – The trunk swells to take the shape of a pumpkin, hence the name.

- European Ash (Fraxinus excelsior) – grows in Europe and some parts of North America. High-demand, durable and Commercially valuable. The heartwood is dark, olive-brown.

- Tamo Ash (Fraxinus Lanuginosa) – Also called Japanese Ash, it is particularly known for a unique figuring pattern resembling peanut shells.

- Oregon Ash

- Pink Ash

- Red Ash

- Swamp Ash

- Mountain Ash

* Not all of the above are necessarily species of ash wood.

How to Buy the Best Quality Ash Wood Online?

Now that you know everything about ash wood properties, you must be looking for the best reliable supplier for top-quality ash timber at wholesale price. Your search ends here. We are a wholesale seller and exporter of ash hardwood and supply to our clients in 20+ countries across Asia, Europe, America, the Middle East, and Australia. Contact us to enquire about the availability and best price for premium ash wood and timber.